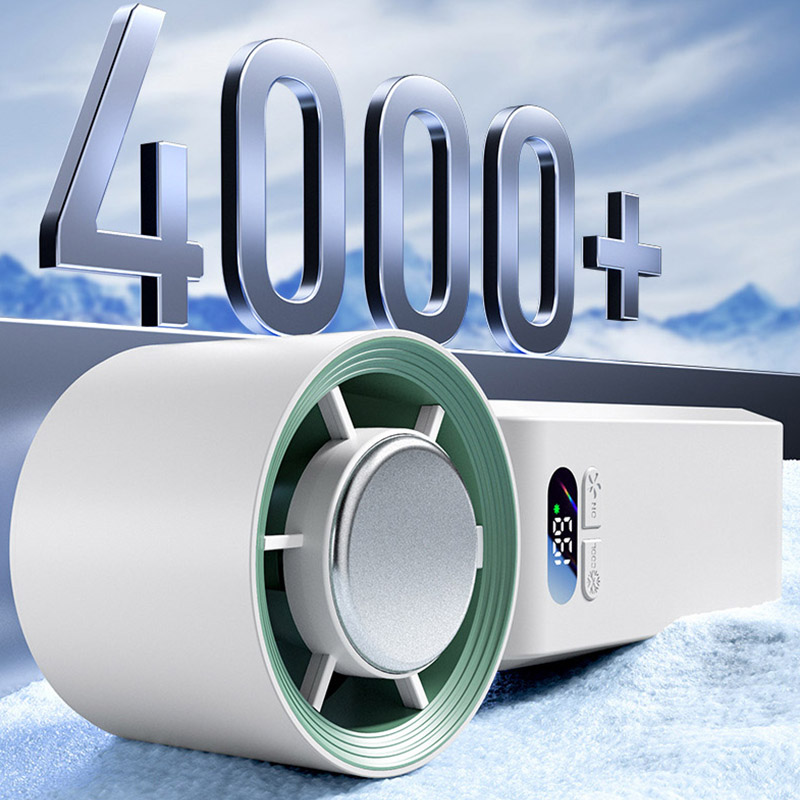

A Handheld Fan Packed with Multiple Standout Features

Upgraded from a traditional fan to a cooling fan, it now delivers significantly improved battery life and a much higher rotation speed.

Peltier Plate / TEC Cooling Chip

1–199 speed levels

90-degree bend design

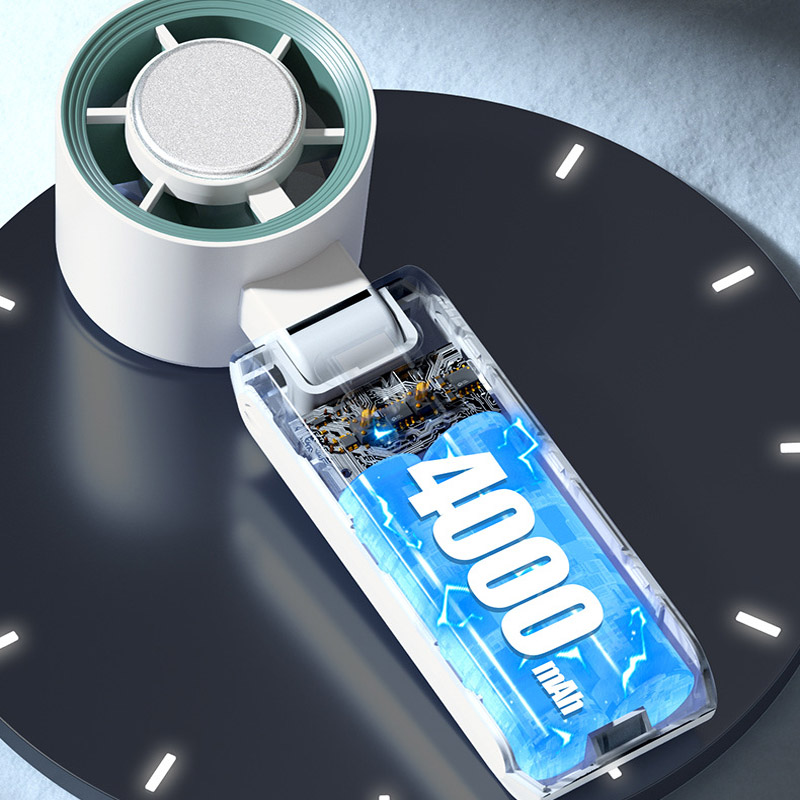

4000mAh large-capacity battery

12,000 RPM motor

Real-time digital display screen

Type-C port

Certified: FCC, RoHS, CE

Engineering Challenges, Refined Solutions

A visual breakdown of how we resolved manufacturing hurdles through structural refinement and process optimization.

Hot-Side Thermal Dissipation Limitation

The cold side of the TEC thermoelectric cooler rapidly decreases in temperature, but insufficient heat dissipation at the hot side causes the cold side temperature to rise quickly, resulting in a short-lived cooling effect.

Manufacturing Process Solutions

Optimize the hot-side heat dissipation structure by integrating a heat-spreading plate/thermal interface material and a properly designed airflow channel on the backside of the TEC cooling module, ensuring efficient hot-side heat removal and stable, continuous cooling at the cold side.

Module Fixation Stability Issue

The customer’s original design relied on a single snap-fit structure to connect the ice-cooling module to the fan body.This fixation method lacked sufficient strength and could loosen during repeated use and vibration.

Structural Reinforcement Solution

We redesigned the connection using a threaded + snap-fit dual fixation structure, significantly improving mechanical strength and long-term stability, ensuring the cooling module remains securely in place during operation.

Initial project discussion and expert review for in-depth evaluation. Design concepts based on customer needs, and estimate costs and timelines. DFM review and custom design services based on customer needs. Develop manufacturing plans and validate them with engineering samples to optimize. Assist with certification feasibility and product certification. Allocate manufacturing resources and coordinate human resources. Coordinate pilot runs, assist mass production launch, optimize processes, and support quality management.From Idea to Product Development Process

Contact UsNeeds Analysis

Concept Design

Solution Integration

Manufacturing Solutions

Certification Support

Resource Allocation

Production Support

Is Your Idea Feasible? Let Us Evaluate It

Share your concept or design, and our engineering team will evaluate manufacturability, cost range, and production options. Leave us a message and get professional feedback quickly.

Reviews

There are no reviews yet.