I. Introduction

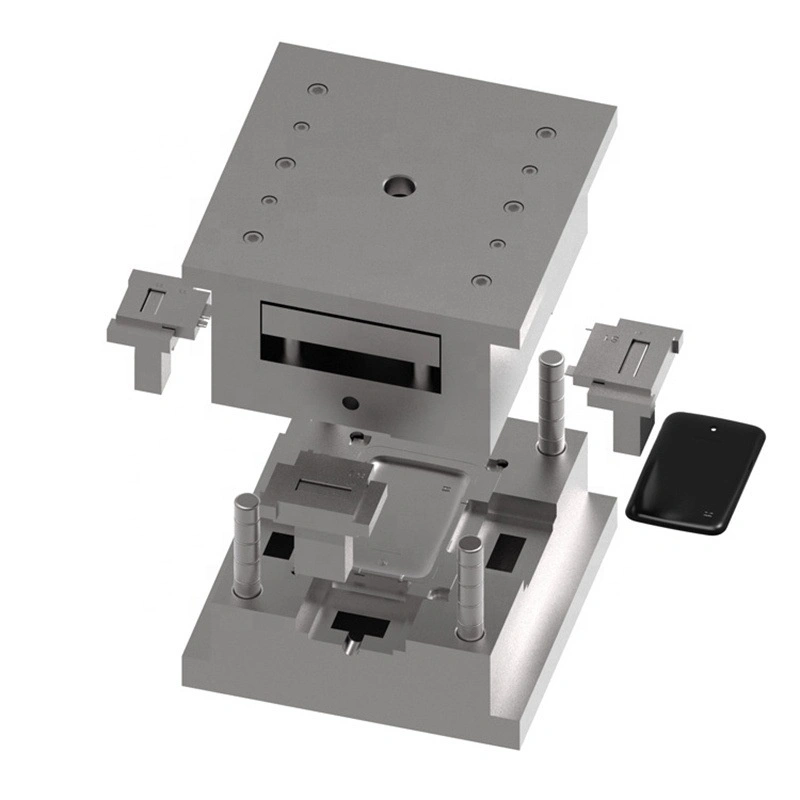

In the modern energy field, charging piles play a crucial role, and the performance of their plastic molds affects the overall quality. This article will conduct an in-depth analysis of the common faults and repair methods for plastic molds used in charging piles, discuss preventive measures, and help improve production efficiency and quality. As part of

plastic injection molding, robust tooling control is essential.

II. Classification and Analysis of Common Faults

1. Wear Faults

Performance and Impact: Under long-term use, the surfaces of the mold core and cavity experience wear due to plastic friction, resulting in a reduction in size and an increase in surface roughness. This leads to dimensional deviations in injection molded plastic parts for charging piles, which in turn affect assembly accuracy.

Principal Analysis: Factors such as the coefficient of friction, surface finish, and tolerance range are involved. The coefficient of friction affects the speed and degree of wear. Wear reduces the surface finish and breaks the tolerance range, making the plastic parts unable to meet the design requirements.

2. Cracking Faults

Performance and Impact: Affected by the impact force of mold opening and closing, cooling shrinkage stress, and material defects, key parts such as the gate and reinforcing ribs are prone to cracking, leading to flash and short shot of plastic parts, affecting the integrity, functionality, and safe use of the parts.

Principal Analysis: It is related to stress concentration, coefficient of thermal expansion, and fatigue strength. An unreasonable structure causes stress concentration to exceed the material’s bearing limit and leads to cracking. The significant difference in the coefficient of thermal expansion between different materials generates stress during cooling due to uneven shrinkage, which can cause cracking. Repeated cycling operations reaching the fatigue strength limit can also lead to cracking.

3. Deformation Faults

Performance and Impact: Due to uneven cooling systems and unreasonable mold structures, the mold may deform as a whole or partially, damaging the shape and dimensional accuracy of the plastic parts. For example, the deformation of the charging pile shell renders it impossible to install normally, thereby affecting both the appearance and function of the charging pile.

Principal Analysis: The inconsistent cooling rate generates thermal stress, insufficient mold stiffness to withstand external forces, and low heat conduction efficiency, leading to high local temperatures, all of which can cause deformation.

4. Jamming Faults

Performance and Impact: During actions such as mold opening and closing and ejection, jamming occurs due to the wear of the guiding mechanism, improper fit clearances, and the entry of foreign objects, causing scratches on the plastic parts and incomplete ejection, affecting production efficiency and increasing costs.

Principal Analysis: The reduction in guiding accuracy (due to the wear of the guiding mechanism), improper fit tolerances, and the increase in friction caused by an imperfect lubrication system can all trigger the jamming phenomenon.

III. Repair Methods and Precautions for Faults

1. Repair of Wear Faults

1.1 Repair Methods: Mild Wear: Restore the size and surface finish by using surface treatments such as polishing and chrome plating. Severe Wear: Replace the damaged parts or repair them using laser cladding technology.

1.2 Precautions: Strictly control the repair accuracy to ensure that dimensional tolerances and surface parameters meet the requirements of plastic molding conditions.

2. Repair of Cracking Faults

2.1 Repair Methods: Small Cracks: Repair them using appropriate welding processes. Large-area or Key-part Cracking: Replace the inserts and re-debug the mold.

2.2 Precautions: Select the appropriate welding materials and parameters based on the mold material, and conduct flaw detection after the repair.

3. Repair of Deformation Faults

3.1 Repair Methods: Cooling System Problems: Inspect and repair the cooling pipes or adjust their layout as needed. Mold Structure Problems: Conduct local modifications or overall optimization designs, and recalculate the relevant parameters.

3.2 Precautions: Avoid damaging other parts during operation, and fully consider the requirements of the plastic molding process.

4. Repair of Jamming Faults

4.1 Repair Methods: Wear of the Guiding Mechanism: Replace the guiding parts and ensure the installation accuracy. Improper Fit Clearances: Readjust the fit tolerances. Entry of Foreign Objects: Clean the foreign objects and improve the protective measures.

4.2 Precautions: Lubricate the replaced guiding parts, conduct multiple adjustments to ensure the fit tolerances, and perform a comprehensive inspection after cleaning to verify the effectiveness of the protection.

IV. Preventive Measures

Daily Maintenance: Clean the residues after production, regularly lubricate the moving parts, and frequently check the wear and deformation conditions of key parts.

Mold Optimization: Reasonably arrange the layout and strengthen the stiffness and strength in the design; strictly control the precision and material quality during manufacturing.

Standardized Operation: Control the process parameters according to the regulations and operate according to the procedures to prevent faults before they occur. For scaling production of charging-pile housings, consider partnering on

custom injection molded parts

with clear DFM rules.

V. Conclusion

Plastic molds for charging piles are crucial to the production of charging piles. Understanding their common faults and repairs, and implementing preventive measures, can ensure the performance of the molds and improve production quality, thereby enhancing efficiency. This is of great significance for promoting the development of the charging pile industry, which requires the attention of industry practitioners. If you need a supplier for scale-up, explore our

plastic injection molding service

and consult an experienced

injection molding manufacturer.