Full-Spectrum Technical Solutions: From Design to Certified Production

Get a Quote Now

DFM Review / DFM Report

Reverse Engineering & 3D Scanning Services

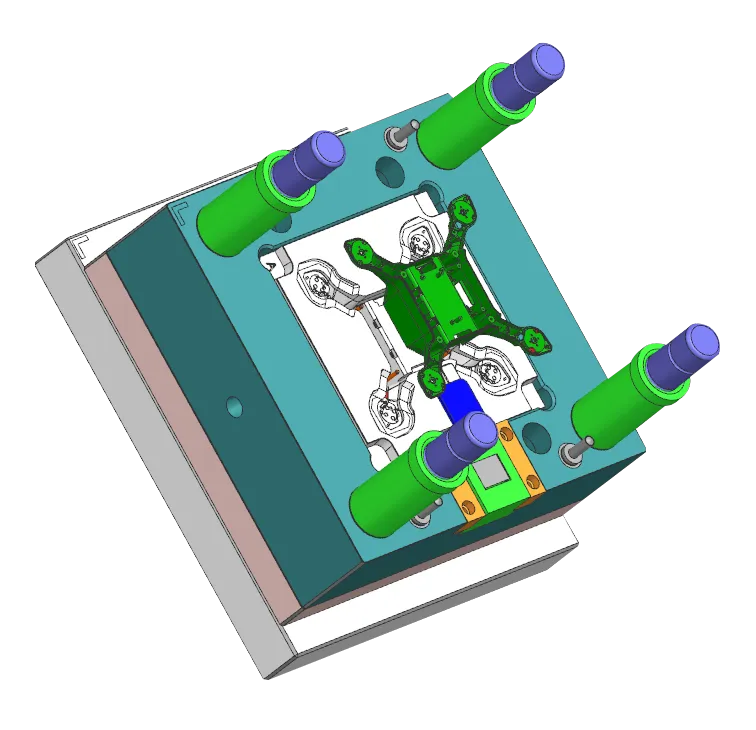

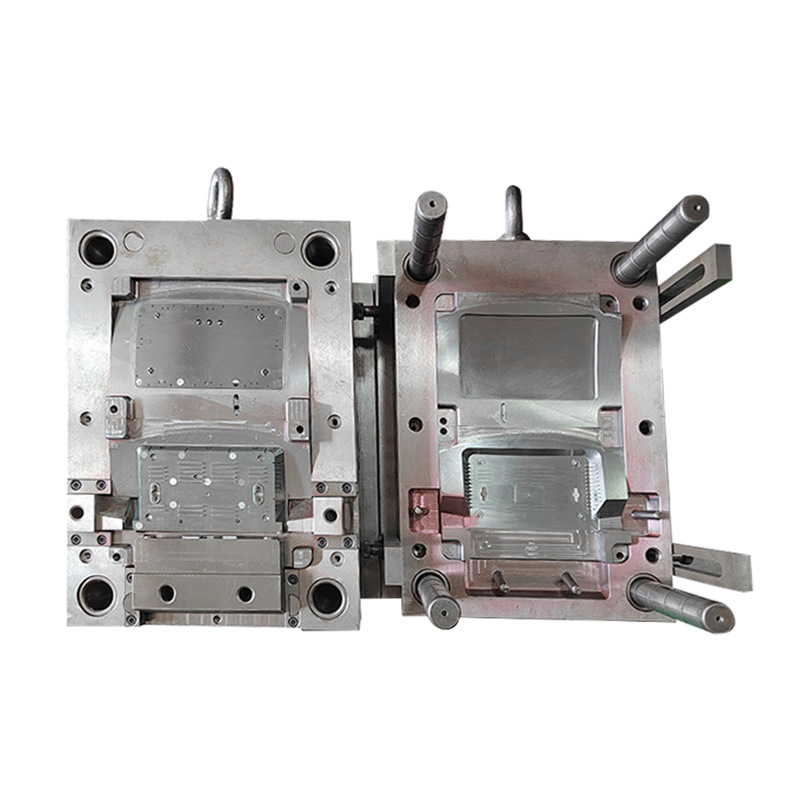

Plastic Product Injection Molding

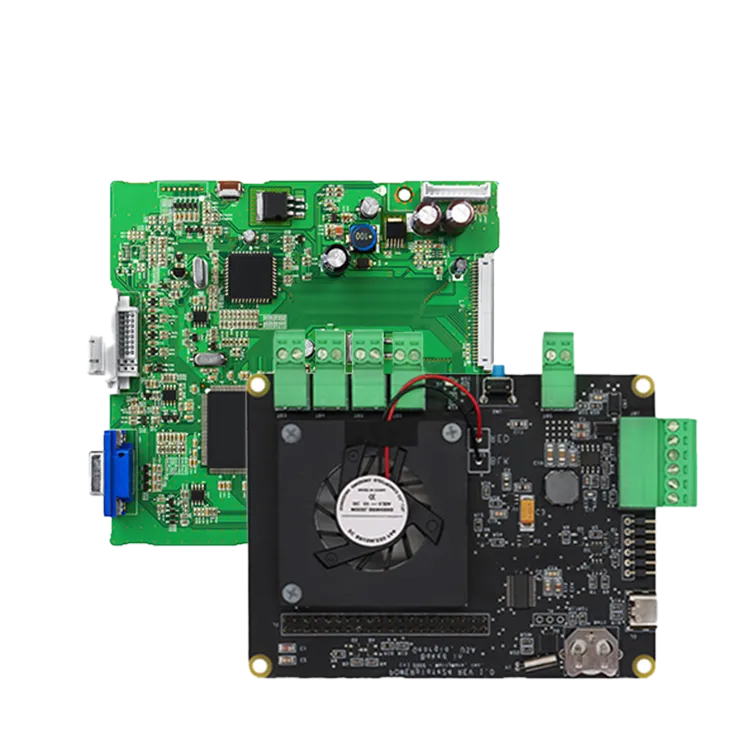

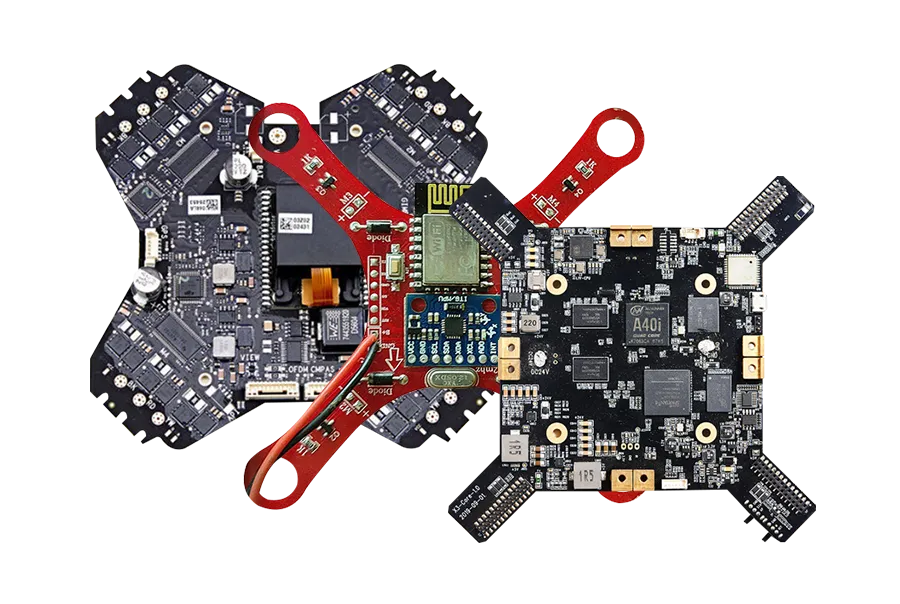

Certify & Deploy: Full-Feature Electronics Development

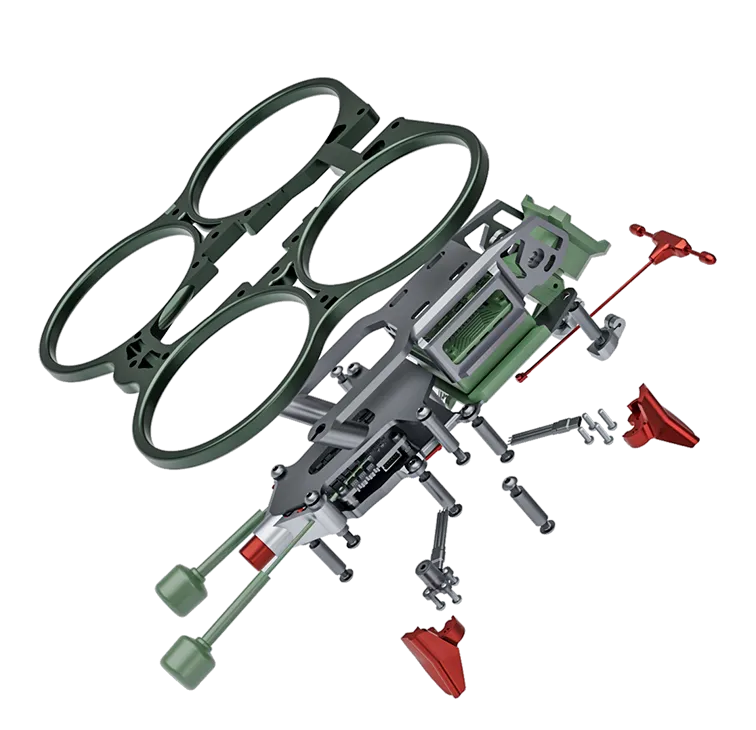

Product Assembly Services

Strictly Protect Your Intellectual Property Rights

Injection Molding Capabilities

Read More| Standards | Details |

| Maximum Part Size | 1200×1000×300mm |

| Minimum Part Size | 11×1mm |

| Mold Cavity Tolerances | ±0.01mm |

| Mold Material | Steel and aluminum tools |

| Mold Type | Single, multi-cavity, and family molds; The production levels we provide: below 1000 times, below 5000 times, below 30000 times, above 100000 times. |

| Part to Part Repeatability | ±0.005mm |

| Tool Ownership | Customer owned |

| Secondary Operations | Mold texture, transfer printing, laser engraving, threaded inserts, and basic assembly. |

| Inspection and Certification Options | Quality reports such as FAI, ISO 9001, IATF16949 |

| Lead Time | 15 business days or less |

End-to-End Drone PCBA Development: From Concept Design to Production

Customization Process

Get a Quote NowProvide your design drawings 3D/2D/Samples

Provide a detailed quote based on your required quantity

Support multiple payment methods

Worldboundgroup will provide detailed DFM reports

Production according to standard process

Reviews

There are no reviews yet.