I. Introduction

In the field of medical device manufacturing, the quotation of injection molds for medical connectors is a complex issue that is affected by many factors. This article will delve into these factors to help readers gain a comprehensive understanding of the quotation mechanism for injection molds used in medical connectors, and provide references for industry insiders to formulate reasonable quotation strategies. For context in

plastic injection molding, understanding these drivers helps align RFQs with quality and cost targets.

1. Mold Design Complexity: A Key Factor Affecting the Quotation

Product Structure

The internal channels of medical connectors are complex. For example, in minimally invasive surgical connectors, the design of the core is complex, and special structures are required for demolding. Additionally, the uneven distribution of the cooling system leads to complex processes and high costs. High-precision threaded and snap-fit structures have small tolerances, and their forming and demolding mechanisms are complex, significantly increasing manufacturing costs.

Parting Surface Design

The parting surface affects the mold processing and product quality. The design of the parting surface for complex connectors must be exact. If there are undercuts, it will increase the difficulty of part assembly, simulation time, and cost.

Demolding Mechanism

Complex-shaped medical connectors require special demolding mechanisms. To ensure accuracy and quality, the movement of the demolding mechanism must be stable and reliable, which requires specialized devices and materials, as well as multiple experimental optimizations, thereby increasing the design difficulty and cost.

2. Mold Material: The Trade-off between Performance and Price

Relationship between Performance and Price

Injection molds for medical connectors require excellent compressive strength, wear resistance, corrosion resistance, and thermal stability. High-performance materials, such as H13 and S136 steel, can meet the performance requirements; however, they are relatively expensive, thereby increasing manufacturing costs.

Influence of Brand and Quality

Materials from well-known brands have excellent quality but are relatively expensive, such as those from Uddeholm in Sweden. Materials of ordinary brands are less costly, but the mold life and precision may be slightly inferior. When choosing, it is necessary to comprehensively consider production requirements, cost budgets, and mold life and precision requirements.

3. Mold Size and Specifications: Important Factors for Cost Variation

Influence of Product Size

For large medical connectors, such as those used for large infusion tubes, the mold requires more materials, energy, and person-hours. The requirements for equipment specifications and precision are also higher, resulting in increased costs.

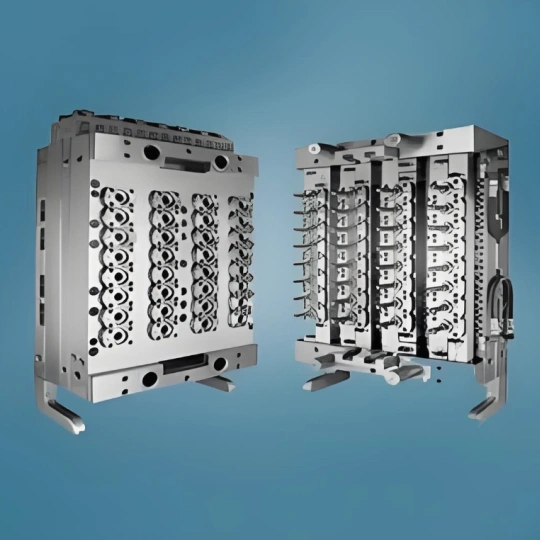

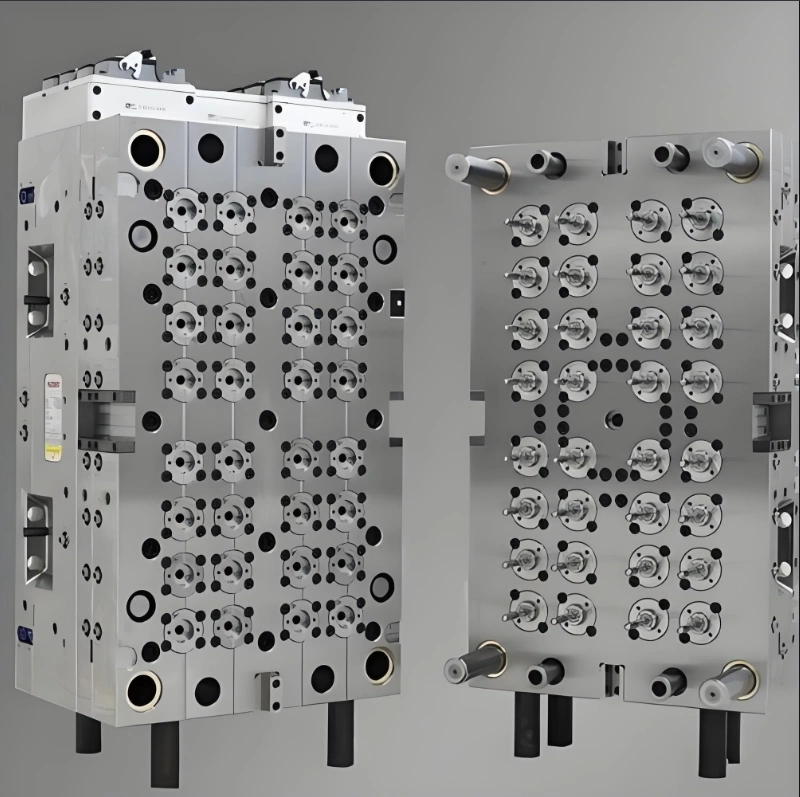

Relationship of Cavity Number

Increasing the number of cavities can improve production efficiency, but the mold structure becomes more complex. Changing from a single cavity to multiple cavities requires a complex gating system to ensure uniform plastic filling. The layout of the runner and ejector mechanism in the multi-cavity mold is complex and requires precise calculation to prevent problems, increasing the design and manufacturing difficulty and cost — considerations that directly impact

injection molded plastic components

programs.

4. Machining Precision and Surface Quality: Quality Improvement and Cost Increase

Improvement of Dimensional Precision

To achieve high precision, advanced equipment and processes such as high-speed milling and slow wire cutting are required. This equipment is expensive and difficult to maintain, with labor costs being relatively high, which in turn increases the machining cost.

Requirement of Surface Roughness

The surface roughness of the cavity and core of the injection mold for medical connectors typically needs to reach a level of Ra 0.8 – Ra 0.2 μm. Multiple fine polishing processes are required, using high-quality materials and equipment. The labor intensity is high, and efficiency is low, which increases the cost. However, good surface quality is crucial for the product’s performance.

5. Production Batch and Service Life: Consideration of Long-Term Cost

Influence of Expected Output

For large-batch production, the mold must be made of high-quality materials and have a robust structure. Long-term production also requires precision machining and regular maintenance, which increases the overall production cost.

Relationship of Mold Life

Long-life molds have a high initial cost but a low replacement frequency, which can significantly reduce shutdown and labor costs in the long term. On the contrary, short-life molds have a low initial cost but a high replacement frequency, resulting in an overall price that may be higher. When selecting a mold, it is essential to consider both production requirements and budget constraints thoroughly.

6. Manufacturing Process and Technical Level: Key Factors for Cost Control

Influence of Machining Process

Advanced processes such as high-speed cutting and electrical discharge machining require high-end equipment. The equipment procurement and maintenance costs are high, and the consumable costs, such as electrode wear and tool wear, are also substantial, directly increasing the manufacturing cost. However, these new processes can improve the precision and efficiency of the mold, shorten the manufacturing cycle, and reduce the long-term cost.

Value of Manufacturer’s Technical Strength

Manufacturers with high technical levels can accurately control all aspects of mold manufacturing, reduce the scrap rate and maintenance cost, and improve the product quality. Although the quotation is relatively high, it can help customers reduce costs in the long term, and its high charge reflects professional value and cost control ability — a reason to select an experienced

injection molding manufacturer.

7. Other Factors: Non-negligible Cost Factors

Cost of Trial Molding and Debugging

Trial molding involves the consumption of raw materials, energy, and labor, and the price increases exponentially with each additional trial molding.

Transportation and Packaging Cost

The transportation distance, mode, and special packaging requirements affect the transportation and packaging cost of the mold. Long-distance transportation or special packaging will significantly increase the price.

Market Supply and Demand Relationship

When the market demand is strong, the mold price will rise; when the order is not saturated, the price may be reduced.

Conclusion

The quotation of injection molds for medical connectors is comprehensively affected by many factors. In actual operation, it is necessary to comprehensively consider all factors, weigh the pros and cons, and formulate a reasonable quotation strategy to ensure mold quality while maximizing economic benefits, meeting market demand for injection molds for medical connectors, and improving industry competitiveness. For RFQs and validation, explore our

plastic injection molding service

alongside

custom injection molded parts

tailored to medical standards.