Introduction

Common surface treatment processes for the plastic shells of multifunctional massage devices include painting, electroplating, silk screening, pad printing, hot stamping, and laser engraving. The following details these surface treatment processes and their respective advantages and disadvantages for the plastic shells of multifunctional massage devices. In finishing for

injection molded plastic parts

produced via

plastic injection molding, choosing the right process balances appearance and durability.

1. Conventional Painting

Principle and Process

Paint is evenly adhered to the plastic shell through a spray gun. The plastic shell is meticulously cleaned, and non-painting areas are carefully masked in the preliminary stage. The air pressure (approximately 0.3 – 0.5MPa), spray width (10 – 30cm), and paint output of the spray gun are precisely adjusted according to the characteristics of the plastic shell. The operation is carried out in an environment with a temperature range of 20°C to 25°C, a relative humidity of 40% to 60%, and adequate ventilation. Subsequently, it can be air-dried naturally (for 24 – 48 hours) or heated in a drying oven (at 50 – 80°C for 30 – 60 minutes).

Advantages

A wide variety of colors can be formulated to meet diverse design requirements; the equipment and material costs are not high, facilitating overall cost control.

Disadvantages

Scratches are prone to occur during daily use, and the wear resistance is poor. When in contact with chemical substances, the paint is susceptible to color changes and corrosion due to insufficient chemical resistance.

2. UV Painting

Principle and Process

After conventional painting, the paint is rapidly cured with the aid of ultraviolet curing equipment. The air pressure of the spray gun (approximately 0.4 – 0.6MPa) and other parameters need to be appropriately adjusted according to the characteristics of the paint. At the same time, the power (80-120W/cm), wavelength (365nm or 405nm), irradiation distance (10-15cm), and time (30-120 seconds) of the ultraviolet lamp tube are precisely set.

Advantages

The paint film is hard and smooth, with strong wear resistance; it has good tolerance to common chemical substances; the ultraviolet curing is rapid, significantly enhancing production efficiency. This finish is common on cases for

custom injection molded parts

requiring high wear resistance.

Disadvantages

The purchase and maintenance costs of dedicated UV curing equipment are high. Strict control requirements are imposed on process conditions, such as paint thickness and ultraviolet irradiation parameters, and problems, including incomplete curing or paint film quality issues, are prone to occur.

3. Electroplating in Aqueous Solution

Principle and Process

Based on the electrolysis principle, through the pretreatment of the plastic shell, controlling the composition of the electroplating solution, current density, and time parameters, a metal film is deposited on its surface.

Advantages

It exhibits a firm metallic texture and luster, significantly enhancing the surface hardness and wear resistance.

Disadvantages

The process has potential environmental pollution hazards and is complex and costly.

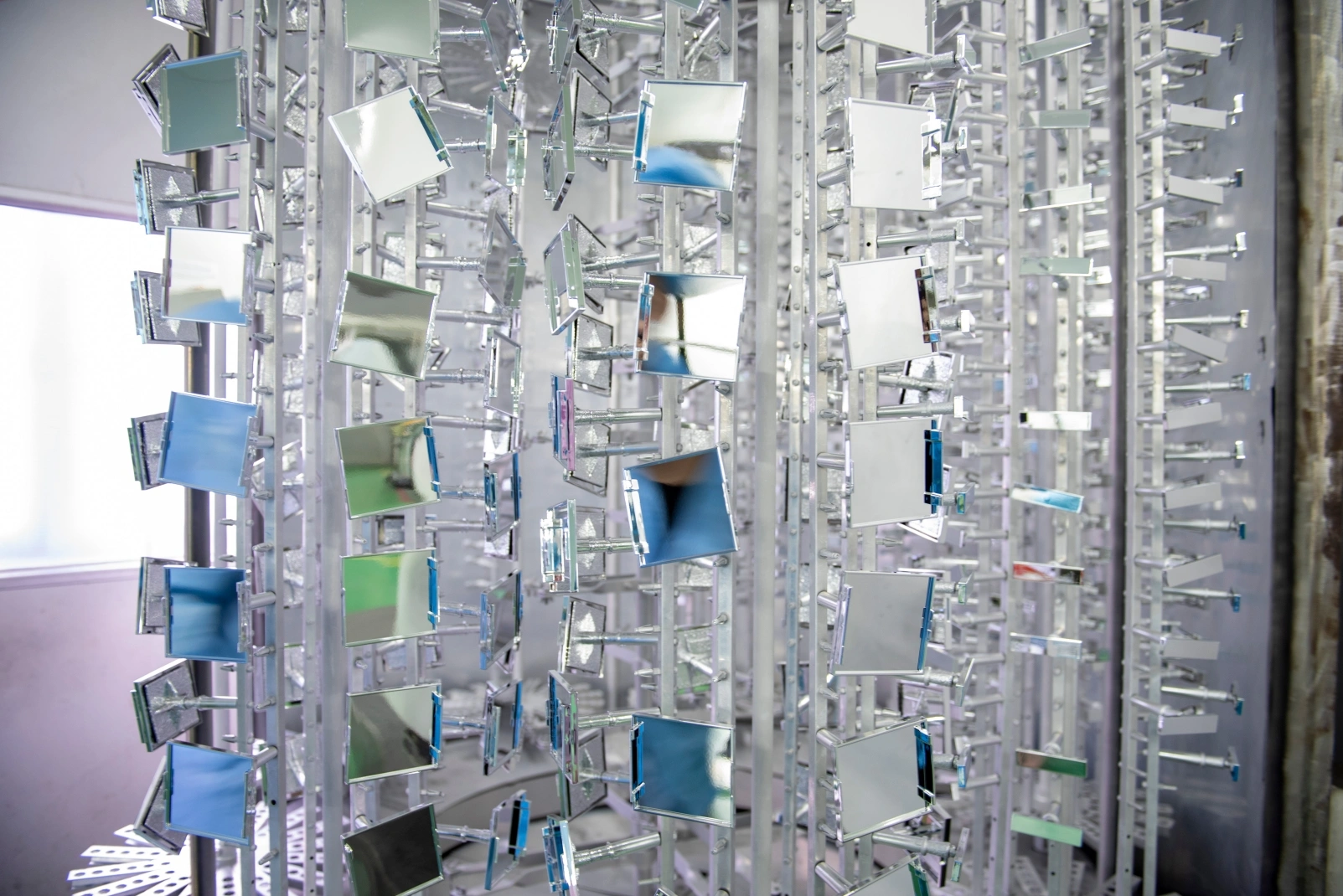

4. Vacuum Electroplating

Principle and Process

In a vacuum environment, the metal is evaporated and then deposited on the surface of the plastic shell, with the deposition rate, film thickness, and other parameters being regulated.

Advantages

The formed metallic texture is fine and uniform, and the environmental performance is relatively good.

Disadvantages

A huge equipment investment is required, and the production efficiency is relatively low.

5. Silk Screening

Principle and Process

By fabricating a silk screen, mixing ink, and controlling parameters such as the pressure and speed of the squeegee, silk screen printing is performed on the plastic shell.

Advantages

It can achieve rich and exact pattern printing with good cost-effectiveness.

Disadvantages

The printing effect of large-area solid colors or gradients is not ideal, and pattern deformation and blurring problems are prone to occur during curved surface printing.

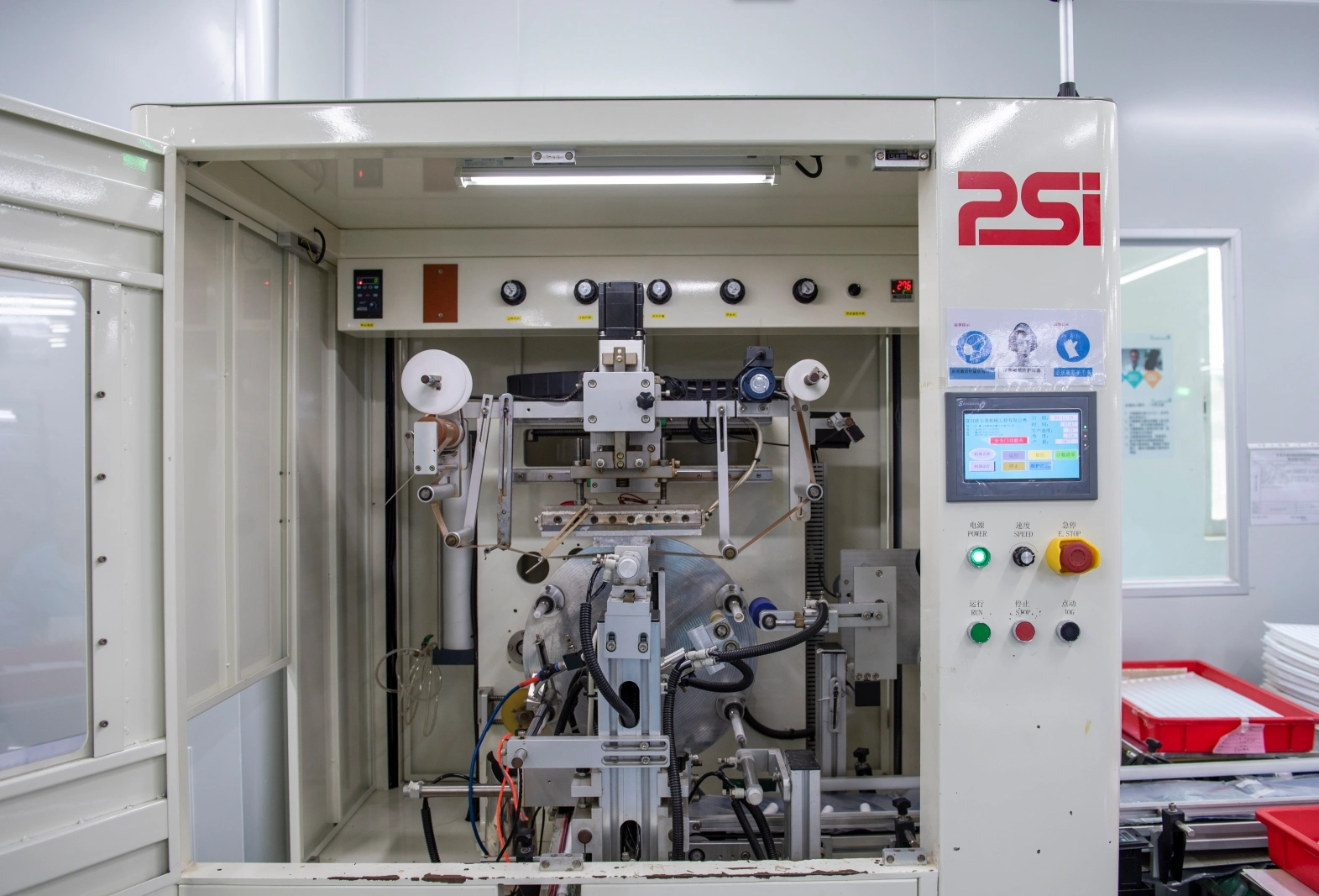

6. Pad Printing

Principle and Process

First, the steel plate is etched, and then the silicone head is used to pick up the ink on the steel plate and transfer it to the plastic shell, with the pressure and contact time of the silicone head being controlled.

Advantages

High-precision printing can be achieved, and it has good adaptability to curved surfaces.

Disadvantages

The production efficiency is relatively low, and the costs of fabricating the etched steel plate, special silicone head, and ink are high.

7. Hot Stamping

Principle and Process

Metal foil is stamped onto the plastic shell using high temperatures and pressure; therefore, parameters such as temperature, pressure, and time must be set appropriately.

Advantages

It presents a high-end and luxurious appearance, and the pattern has good durability.

Disadvantages

The cost is high, and it is challenging to modify the design due to limited flexibility.

8. Laser Engraving

Principle and Process

Laser engraving is carried out on the plastic shell by using a laser beam, with parameters such as laser power and scanning speed being adjusted.

Advantages

It has high engraving precision and a significant degree of freedom, does not damage the material, and is environmentally friendly.

Disadvantages

The investment in purchasing the equipment is substantial; selection should align with your

plastic injection molding service

specifications and target costs.