Our Focus Areas in Product Development

View More Product Cases

Products Designed for Relaxation, Sleep & Inner Balance

We focus on developing and manufacturing wellness-oriented products that support relaxation, sleep, mindfulness, and emotional well-being.

From calming, soothing concepts to sleep-aid and mindfulness products, we work closely with our clients to turn ideas and creative concepts into real, market-ready products through professional OEM and ODM services.

Fun, Joy & Interactive Products

Playful, interactive products created to bring joy and positive emotional experiences into everyday life.

From fun alarm clocks to decision-making gadgets, we help brands turn playful ideas into reliable, manufacturable products.

Feasibility Check: See If Your Idea Can Work

Contact UsUnderstand Your Needs

- Collect your MOQ and order details

- Define product functions and features

- Select materials and surface finishes

- Verify certifications and compliance

- Understand target markets for export

Engineering Evaluation

- Assess product feasibility

- Estimate design and certification costs

- Provide rough production cost

- Evaluate design and manufacturing timelines

- Ensure manufacturability and quality

Feasibility Report & Customized Solution

- Deliver professional feasibility report

- Tailor solutions to your budget

- Customize according to your requirements

- Reduce risk and uncertainty

- Support informed decision-making

Your ideas are used solely for evaluation and will not be disclosed. Please rest assured.

From Design to Engineering: A Full End-to-End Making Solution

Contact UsLearn About Appearance Design Requirements

According to Your Needs and Recommendations

Understand Product Functions

According to Your Needs and Recommendations

Product Design: Appearance & Structure

Build 3D Models According to Product Appearance and Electronic Component Layout

Product Rendering

Showcase the product using 3D model rendering for visual presentation.

3D Printed Prototype Samples

3D printed exterior with purchased components assembled for prototype verification.

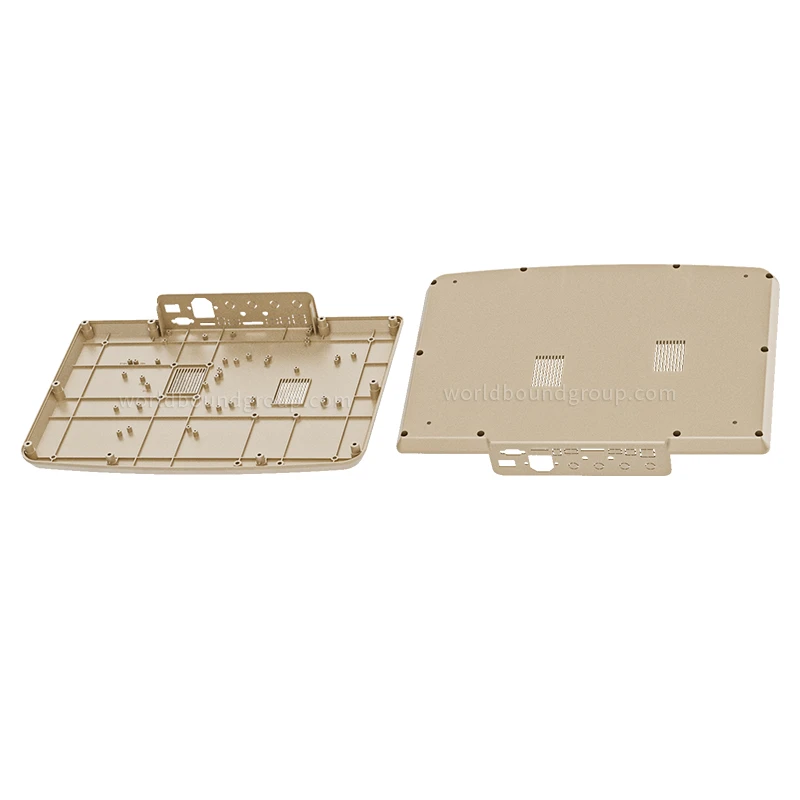

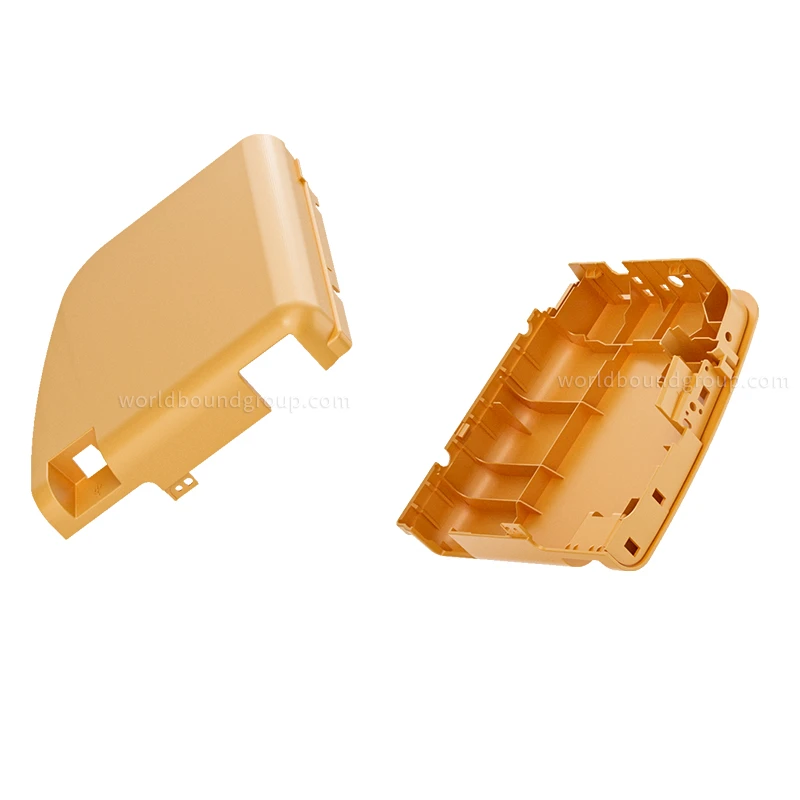

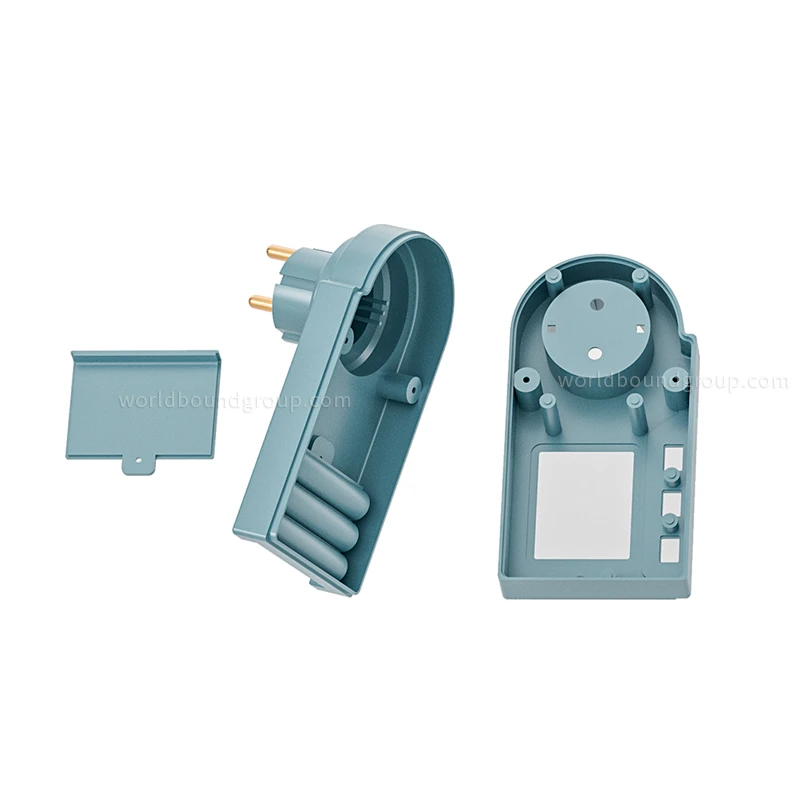

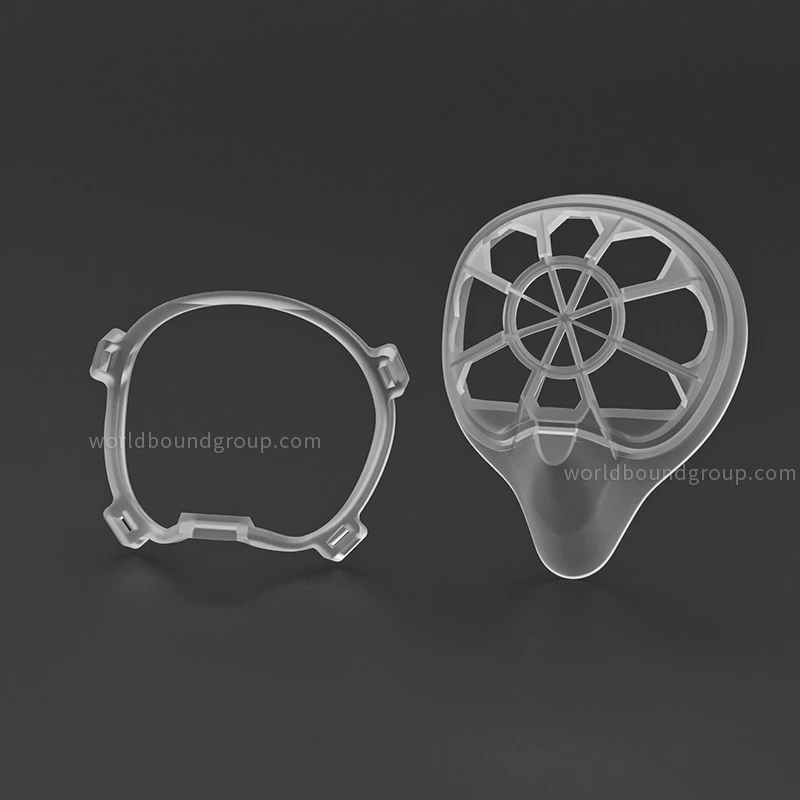

Cosmetic Part Tooling Evaluation

Evaluate mold costs for cosmetic exterior parts, including injection, and other tooling.

Component Unit Price Evaluation

Evaluate component unit prices based on order quantities.

DFM Review & Final Production Quote

DFM report with production-ready quote and manufacturing plan.

Your ideas are used solely for evaluation and will not be disclosed. Please rest assured.

End-to-End OEM/ODM Production Workflow

A clear and streamlined process from DFM to delivery.Sign the production contract

Create a production lead-time and delivery contract based on the customer’s MOQ.

Pay 50% Deposit

Production scheduling will begin upon receipt of the deposit.

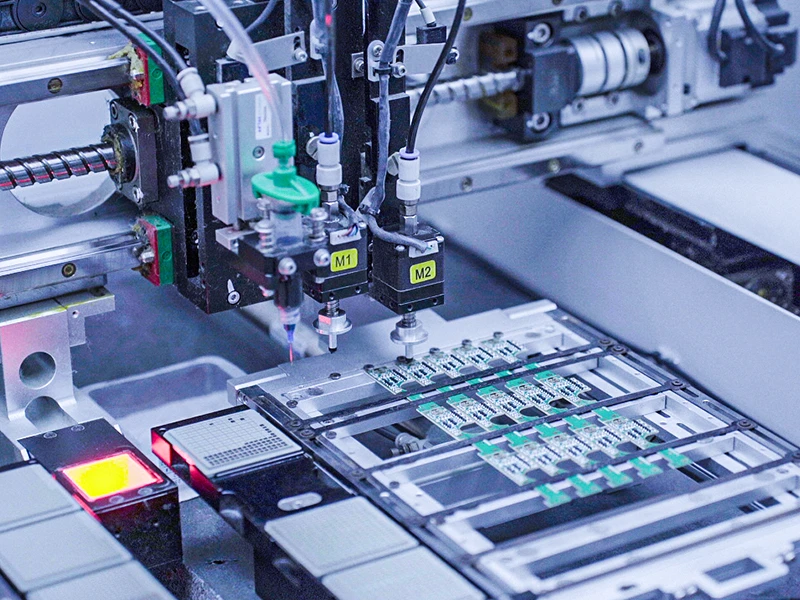

Start Production

Mold fabrication, injection molding, PCBA production, material procurement, assembly, and testing.

Conduct Required Certifications

Use the first batch of products for concurrent certification to accelerate delivery.

Pre-Shipment Inspection

Upon completion of production, a third-party inspection can be arranged upon request.

Pay the remaining 50% Balance

Upon approval of the inspection, the remaining balance shall be paid.

Load the Container

Ship the goods according to the customer’s designated port or shipping method.

Customer Service

24/7 customer support with rotating service teams for faster, better after-sales assistance.

Your project will be covered by a confidentiality agreement, so you can rest assured.

Where Do You Prefer Your Product to Be Manufactured?

worldboundgroup operates factories in China, Vietnam, and Indonesia—choose the location that best fits your needs.Worldboundgroup China Factory

Founded in 2002, Worldbound Group specializes in intelligent precision manufacturing, integrating upstream and downstream supply chains through collaborative innovation to become a comprehensive enterprise group spanning design, production, and service.

2002

Establishment

1850

Team members

58000㎡

Factory Area

Worldboundgroup Vietnam Factory

Worldbound Group Vietnam Factory produces electronic toys, consumer electronics, and cosmetic packaging in 200,000㎡ smart facilities with automated lines and R&D, backed by a "quality-first" system certified to ISO9001, BSCI, and GSV.

2019

Establishment

2100

Team members

200000㎡

Factory Area

Worldboundgroup Indonesia Factory

Worldbound Group Indonesia Factory, established in 2024, produces AI-powered smart electronics and appliances. It is equipped with advanced production facilities in a self-built industrial base to drive intelligent manufacturing innovation in Southeast Asia.

2024

Establishment

1500

Team members

200000㎡

Factory Area

Why Choose WorldboundGroup?

About UsFactories in Three Countries

Choose from our manufacturing facilities in China, Vietnam, and Indonesia.

Professional Export Customs Team

25 years of export experience with official customs clearance and export qualifications.

30 Years of Product Design Experience

Industrial design, structural design, mold design, and PCBA design.

25 Years of Manufacturing Experience

Experienced in serving leading brand clients from the United States and Japan.

Integrated Design & Manufacturing

Both design and manufacturing are completed in-house.

Certified to International Standards

Accredited with ISO9001, ISO14001, SMETA, SCAN, ASTM, SGS, ROHS, and more.

Strict Quality Control System

IQC / IPQC / OQC / FQC with traceable records and on-site engineers

Strong Supply Chain Integration

Plastic + die casting + CNC + assembly, and long-term partners for PCBA & electronics.

About the worldboundgroup team

You are always welcome to visit us at any time.

Featured Blogs and News

Read MoreFrequently Asked Question

For more information, please contact usMOQ depends on the level of customization.

For logo printing: usually 500–1000 pcs

Full custom ID/structure/function is subject to evaluation after confirming requirements.

For stock models with logo: around 10–15 days

For full custom OEM/ODM, it usually takes 30–45 days, depending on the complexity