Medical devices are an indispensable and essential part of the modern medical system. The quality and safety of their products have a crucial impact on the treatment effect and the life safety of patients. As auxiliary components of medical devices, medical device accessories also play a pivotal role. Among them, the three-way connector, as a kind of medical device accessory, has extensive applications and essential functions. It can achieve various treatment purposes, such as infusing drugs and monitoring blood pressure, improving medical efficiency and quality.

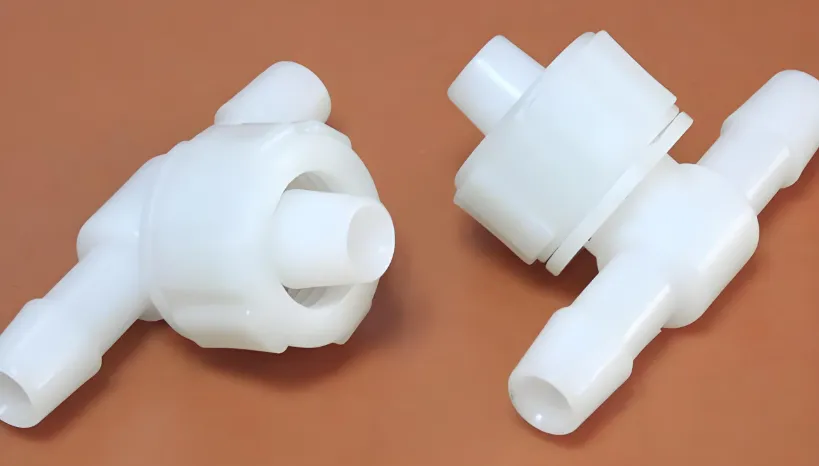

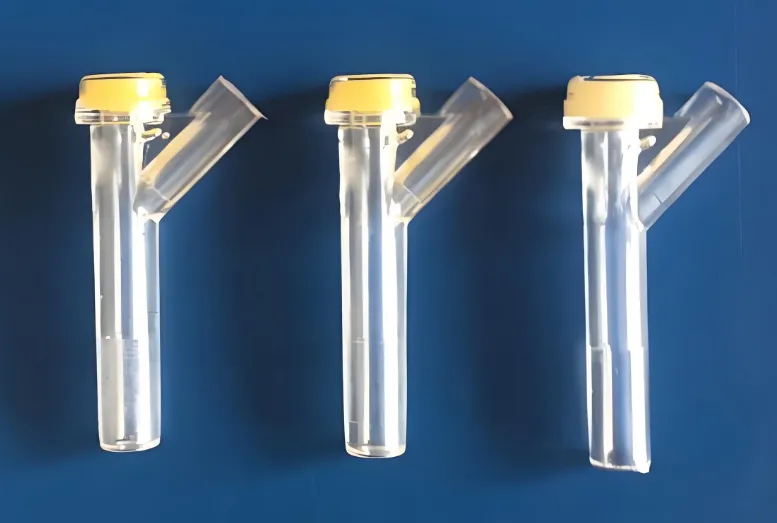

The basic structure of the three-way connector includes a central pipeline and two branch pipelines. The flow direction and flow rate of liquids, gases, or drugs can be controlled by adjusting the switch. In medical devices, the three-way connector is usually located at the end of the infusion device. By changing the valve, the input ratio and flow rate of different drugs can be controlled to meet the treatment needs of patients.

The design of the three-way connector must be exact to prevent fluid leakage and ensure the equipment’s optimal performance. Designers must consider various factors, such as the nature of the fluid, working pressure, and temperature, and comply with relevant regulations and standards. In the manufacturing process, manufacturers adopt precise processing technologies and materials to ensure the accuracy and reliability of the three-way connector. All products undergo strict quality inspections before leaving the factory to ensure they are free from defects.

With the continuous advancement of medical technology, the requirements for medical devices are increasing steadily. Therefore, in the future, the three-way connector may be more intelligent, personalized, and environmentally friendly. For example, a three-way connector that can automatically adjust fluid pressure and flow direction, or a product made of degradable, environmentally friendly materials. However, this also presents numerous challenges, including improving production efficiency, reducing costs, and ensuring product quality and safety. In addition, with the global development of medical technology, meeting the regulatory and standard requirements of different countries and regions poses a significant challenge that manufacturers must face.

As an integral part of medical equipment, the quality and performance of the three-way connector for medical device accessories directly impact the medical efficacy and patient safety. Therefore, strict requirements are needed for the design, manufacturing, and quality control of the three-way connector. Worldbound Group was established in 2002. With intelligent manufacturing and precision manufacturing as its core, it has evolved into a smart manufacturing enterprise group that integrates design, innovation, service, and production. Worldbound Group has earned the trust and praise of its customers through its strong production capabilities, excellent technical expertise, exceptional service, and favorable cost-effectiveness. Moreover, it possesses strong injection molding and customization capabilities, enabling it to produce customized products according to customers’ specific needs. Welcome to Dongguan Worldbound Plastic Products Co., Ltd.