One-stop processing and production services for plastic products and electronic products are a comprehensive production method, aiming to provide customers with one-stop services ranging from product design and mold making to molding and assembly. Now, let me introduce you to one-stop processing and production services.

One-stop processing and production services have the following advantages:

1. Time and labor saving: One-stop services complete multiple links such as product design, mold manufacturing, molding, assembly, and testing in one manufacturer, simplifying the production process and shortening the time to market.

2. Cost reduction: One-stop services reduce the communication and logistics costs between enterprises and multiple suppliers. At the same time, it reduces intermediate links, helps to reduce production costs, and improves efficiency.

3. Quality assurance: One-stop services usually have a strict quality control system, which can ensure the quality of products at all links and improve the consistency and reliability of product quality.

4. Risk reduction: Since the enterprise provides the full-process service, the risks to customers are also correspondingly reduced, because problems can be solved internally.

With the development of the global manufacturing industry, an increasing number of enterprises are seeking one-stop solutions to focus more on their core businesses. At the same time, with the advancement of technology and improvements in production efficiency, the cost of one-stop processing and production services is gradually decreasing. Therefore, overall, the market prospects for one-stop production services for plastic products and electronic products are optimistic. However, enterprises must continually improve the quality of their services to stay competitive in the face of market challenges and changes.

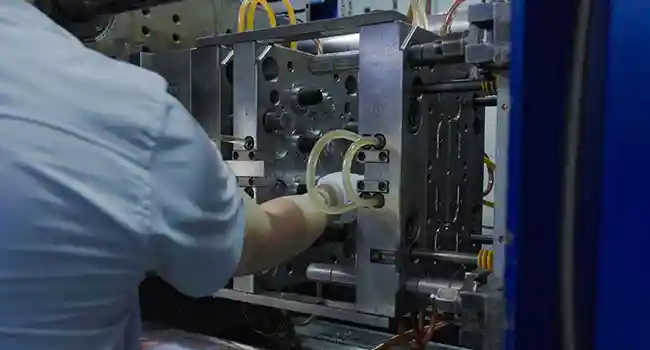

Worldbound Group stays current with the times and follows market trends. It is also a manufacturer of one-stop processing and production services for plastic products and electronic products. Dongguan Worldbound Plastic Products Co., Ltd., a subsidiary of Worldbound Group, mainly produces molds, toys, electrical accessories, medical device accessories, home appliance accessories, electronic products, small household appliances, and pet supplies, providing a complete set of solutions from product design, precision mold manufacturing, injection molding and assembly, and after-sales service for high-end brands.

Guangzhou Qihuan Electronic Technology Co., Ltd., a subsidiary of Worldbound Group, has its own PCB electronic production workshop. The company has 22 years of experience in the field of one-stop electronic product manufacturing in PCBA design, manufacturing, and PCB assembly. It features a strong, fully integrated, and automated PCB manufacturing and SMT chip processing technology, specializing in the production of various single-sided and double-sided PCB circuit boards, multi-layer PCB circuit boards, rigid-flex boards, high-precision HDI boards, and metal substrate boards. At the same time, it provides component purchasing on behalf of customers, SMT chip processing, DIP plug-in post-welding, and finished product assembly and testing. Suppose you need one-stop processing and production services for plastic products and electronics. In that case, you are welcome to visit and explore the services offered at Dongguan Worldbound Plastic Products Co., Ltd. We provide one-stop processing and production services for both plastic and electronic products.