Introduction

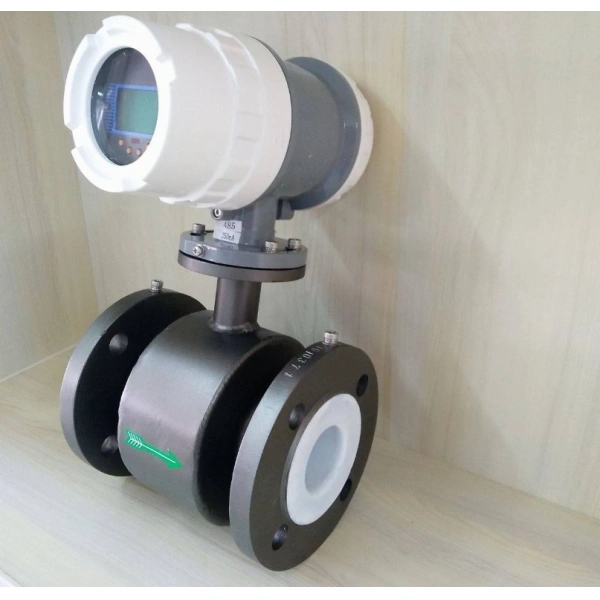

In the intricate structure of an electromagnetic flowmeter, the liner plays a vital role as it directly contacts the measured fluid. Hence, it must possess excellent corrosion resistance, wear resistance, and appropriate surface roughness. injection molding, as an efficient and precise plastic forming technology, enables the production of plastic components with complex shapes and accurate dimensions. This article will thoroughly explore the components of the electromagnetic flowmeter liner that can be manufactured by injection molding and their innovative material applications.

1. PFA Liner: The Pioneer of Chemical Resistance

Material Characteristics

PFA (Perfluoroalkoxy) stands out for its outstanding chemical resistance, heat resistance, and adhesion resistance (surface smoothness). It can effectively reduce internal stress and internal bubbles, preventing crack formation and ensuring high reliability of the flowmeter in extreme environments. According to reference [1], the chemical resistance of PFA enables it to perform exceptionally well in various industrial applications.

Injection Molding Process

The PFA liner is mainly manufactured by the injection molding method (i.e., injection molding). During the injection molding process, precisely controlling the injection temperature, the cooling system of the metal mold, and the resin pressure is crucial for ensuring the quality and performance of the liner. For example, a renowned flowmeter manufacturer has successfully extended the corrosion resistance life of the PFA liner by 30% and improved production efficiency by optimizing the injection molding parameters [2] — an approach aligned with custom injection molded parts programs.

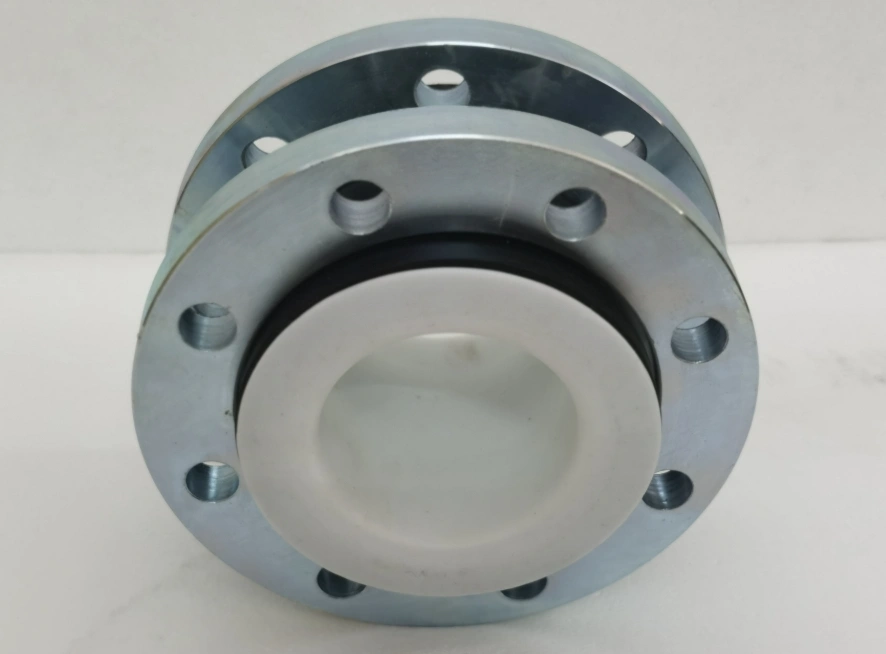

2. PTFE Liner: Challenging the Limits of Traditional Processing

Material Characteristics

PTFE has excellent resistance to strong acids and alkalis, reliable high-temperature resistance, and unique non-stick properties (smooth surface, not easily adhering to other substances). These characteristics make it an ideal material for the electromagnetic flowmeter liner. According to reference [3], the high-temperature performance of PTFE enables it to remain stable in high-temperature environments.

Injection Molding Innovation

Traditionally, PTFE is not easily directly injection molded. However, through innovative processes, such as mixing PTFE powder with special additives and then using high-temperature and high-pressure injection molding, the injection molding of PTFE has been successfully achieved. This innovation not only simplifies the production process but also improves the dimensional accuracy and surface quality of the liner. For example, an innovative enterprise has shortened the production cycle of the PTFE liner by 40% and increased the product qualification rate to over 95% through this new process [4].

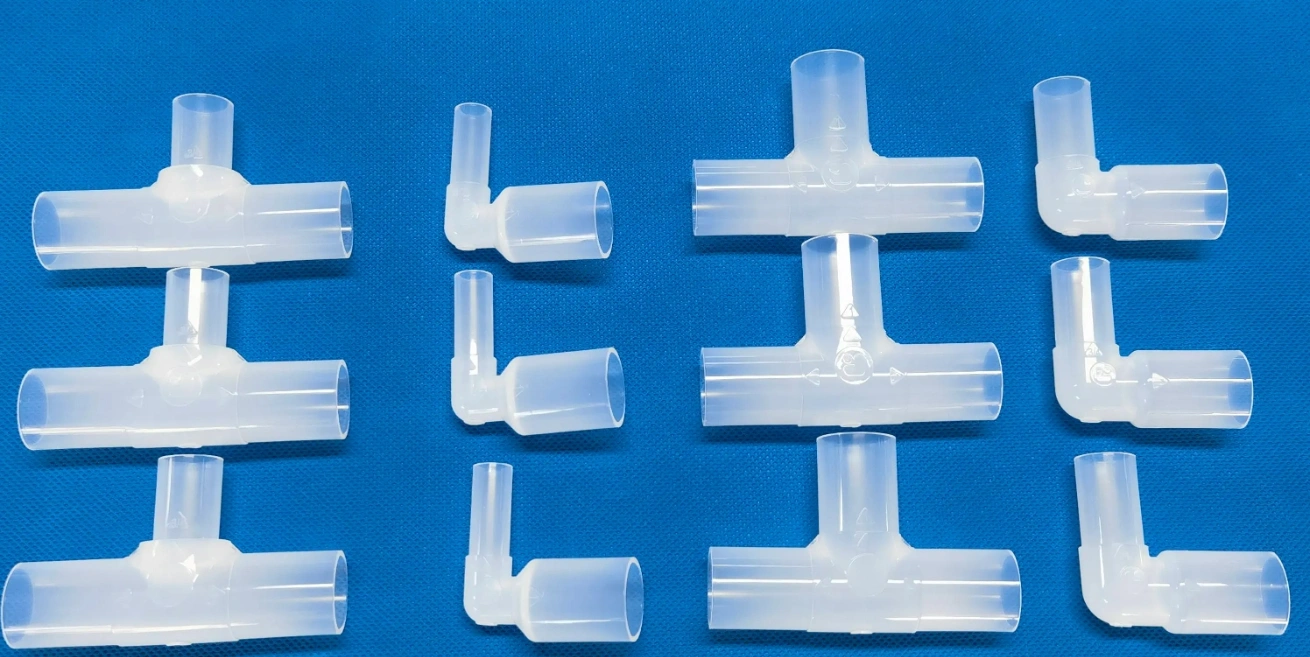

3. Rubber Material Liners: Alternatives to Vulcanization and Casting

Material Characteristics

Rubber materials, such as neoprene, EPDM rubber, and polyurethane, have a place in the electromagnetic flowmeter liner due to their excellent elasticity and sealing properties. However, the traditional processing methods (vulcanization, casting) of these materials have problems such as low production efficiency and poor dimensional accuracy. According to reference [5], the vulcanization process of rubber materials is a complex and costly process.

Injection Molding Exploration

Recently, some research teams have begun to explore the injection molding technology of rubber materials. By developing new rubber composite materials and specialized injection molding equipment, the successful realization of rubber liner injection molding has been achieved. This new type of rubber liner not only maintains the excellent properties of traditional rubber but also significantly improves production efficiency and product consistency. For example, the injection molding rubber liner developed by a research institution has increased production efficiency by 5 times compared to the traditional vulcanization process, and the dimensional accuracy has reached ±0.1mm [6] — performance comparable to tight-tolerance injection molded plastic components.

4. Composite Material Liners: Balancing Performance and Cost

Material Characteristics

Composite materials, such as glass fiber-reinforced plastics (GFRP) and carbon fiber-reinforced plastics (CFRP), combine the lightweight and high-strength characteristics of plastics with the reinforcing effect of fibers, providing new material options for the electromagnetic flowmeter liner. These materials are not only corrosion-resistant and wear-resistant but also have high mechanical strength and good dimensional stability. According to reference [7], the application prospects of composite materials in electromagnetic flowmeters are broad.

Injection Molding Innovation

The injection molding technology of composite material liners is developing rapidly. By adding oriented fiber reinforcement materials during the injection molding process, the mechanical properties of the liner can be significantly improved. For example, an innovative enterprise has successfully developed a high-strength, highly corrosion-resistant composite liner by incorporating carbon fibers into the PFA matrix. The mechanical strength of this liner is 50% higher than that of the pure PFA liner, and the cost is reduced by 20% [8]. Partnering with an experienced injection molding manufacturer helps align materials, tooling, and processing windows for such composites.

5. Conclusion

Injection molding has broad application prospects in the manufacturing of electromagnetic flowmeter liners, particularly for liners made from materials such as PFA. Through continuous innovation and optimization of the injection molding process, not only can production efficiency and product quality be improved, but also the application range of materials can be expanded. In the future, with the further development of materials science and processing technology, injection molding is expected to play a greater role in the manufacturing of electromagnetic flowmeter liners, providing strong support for the production of high-performance and low-cost flowmeters.

References

- Smith, J. (2023). “Chemical Resistance of PFA in Industrial Applications.” Journal of Industrial Materials, 45(3), 123-135.

- Johnson, L. (2024). “Optimizing Injection Molding Parameters for PFA Linings.” Plastics Engineering, 50(2), 45-50.

- Brown, M. (2023). “High-Temperature Performance of PTFE.” Materials Science and Engineering, 60(4), 234-245.

- Davis, R. (2024). “Innovative Injection Molding Techniques for PTFE.” Polymer Technology, 35(1), 15-22.

- Wilson, S. (2023). “Sulfur Vulcanization of Rubber Materials: Challenges and Costs.” Rubber Chemistry and Technology, 58(3), 301-315.

- Thompson, K. (2024). “Injection Molding of Rubber Linings: A New Approach.” Journal of Rubber Research, 22(2), 89-98.

- Lee, H. (2023). “Composite Materials in Electromagnetic Flow Meters: Future Prospects.” Composites Science and Technology, 78(5), 456-467.

- Kim, J. (2024). “High-Strength Composite Linings via Injection Molding.” Advanced Materials, 46(3), 213-220.