Technical Principle Comparison

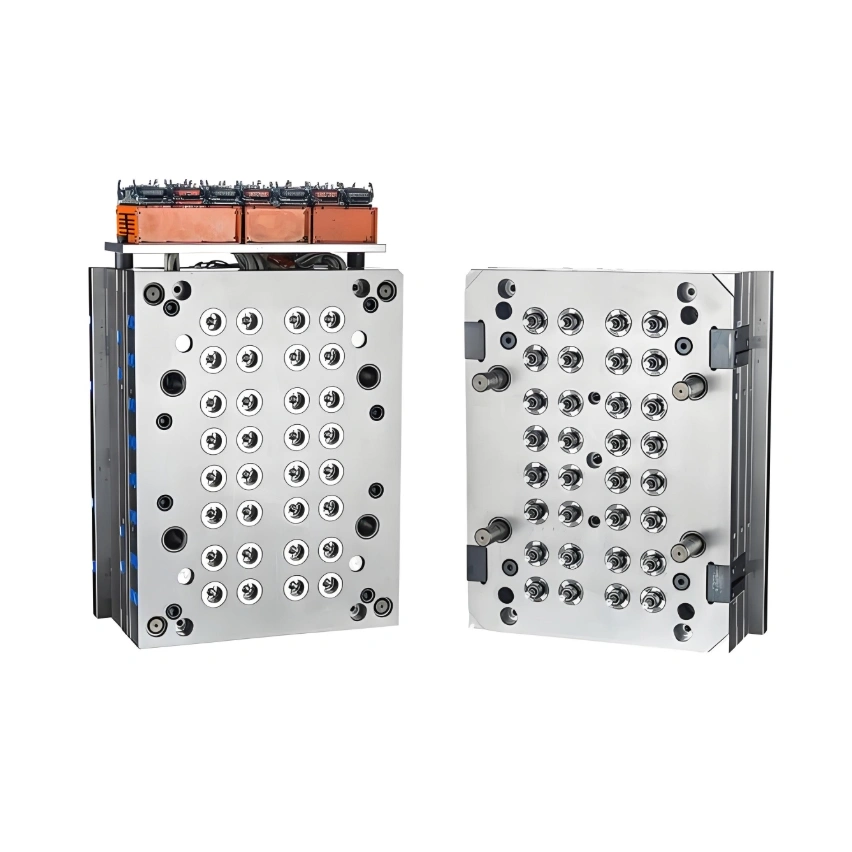

Hot Runner System

Core Mechanism: Integrates embedded heating elements (heating rods/coils) with precision temperature control systems to maintain molten plastic in the runner system, eliminating cold slug formation.

Critical Components: Comprises heated nozzles, distribution manifolds, and thermal controllers. Constructed from high-temperature-resistant alloys (e.g., titanium) for operational stability.

Cold Runner System

Traditional Operation: Relies on natural cooling of the injection system to solidify runners, requiring post-molding operations (trimming/recycling). Characterized by lower automation levels.

Design Features: Simplified structural configuration with lower initial investment, but incurs significant long-term costs associated with scrap management.

Performance & Cost Analysis

Hot Runner Advantages/Limitations

Advantages:

Material Efficiency ≥98%: Virtually eliminates runner waste, ideal for premium materials (e.g., PEEK, medical-grade PC).

Cycle Time Reduction (30-50%): Eliminates cooling time for runners, enabling thin-wall part cycles as low as 5 seconds.

Process Consistency: Uniform melt temperature minimizes defects such as weld lines and warpage, which are critical for precision components (e.g., optics, connectors).

Limitations:

High Initial Investment: 30-50% higher mold costs compared to cold runners, challenging for low-volume production.

Maintenance Intensity: Requires regular carbon deposit removal and risk of downtime due to heating element failures.

Cold Runner Applications

Cost-Effective for Small Batches: Optimal for production volumes <100k units.

Design Flexibility: Accommodates complex gate configurations (multi-gate/irregular runners) without thermal management requirements.

Selection Criteria

Production Volume

Hot Runner Viability Threshold: Economically justified when scrap costs exceed mold cost differential (recommended >500k units).

Material Characteristics

Thermally Sensitive Polymers: Cold runners are preferred for heat-sensitive materials (e.g., PVC, PETG) to prevent degradation.

High-Flow Resins: Hot runners optimize performance for low-viscosity materials (e.g., PA, PP) by reducing pressure drop.

Product Specifications

Aesthetic/Precision Requirements: Hot runners recommended for Class A surfaces (e.g., automotive lighting, medical devices).

Automation Compatibility: Enables lights-out manufacturing with reduced human intervention.

Industry Case Studies

Hot Runner Applications

Automotive: Bumpers, interior components (20% material savings, 40% cycle time reduction).

Consumer Electronics: Smartphone casings, laptop parts (gate mark elimination for premium finishes).

Cold Runner Use Cases

Prototype Development: Cost-effective for small-scale trials and R&D.

Commodity Products: Suitable for low-value items (e.g., packaging, household plastics).

Technological Developments & Recommendations

Smart System Integration

IoT-Enabled Monitoring: Real-time tracking of thermal and pressure parameters minimizes downtime risks.

Advanced Heating Elements: Ceramic-based heaters improve energy efficiency by 15-20%.

Hybrid System Solutions

Combination Approach: Merges hot runner efficiency with cold runner flexibility in multi-cavity molds.

Conclusion

The selection between hot and cold runner systems should consider production scale, material properties, quality requirements, and lifecycle costs. Hot runner systems are the optimal choice for high-volume, precision injection molding plastic parts, while cold runners remain indispensable for low-volume, flexible production environments. For injection molding companies seeking optimal solutions, understanding these technical distinctions is crucial for making informed decisions that balance cost and performance in plastic injection molding service operations.