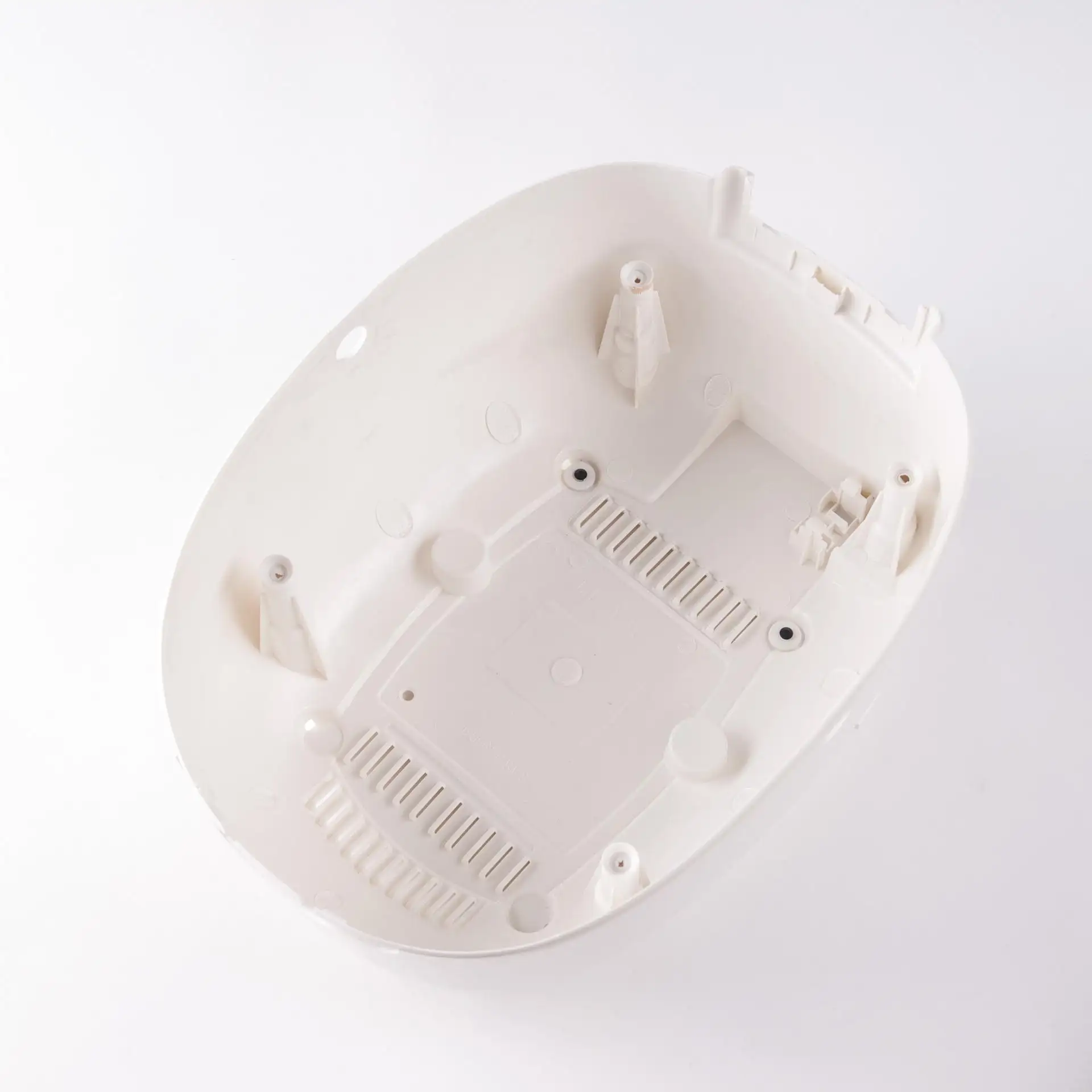

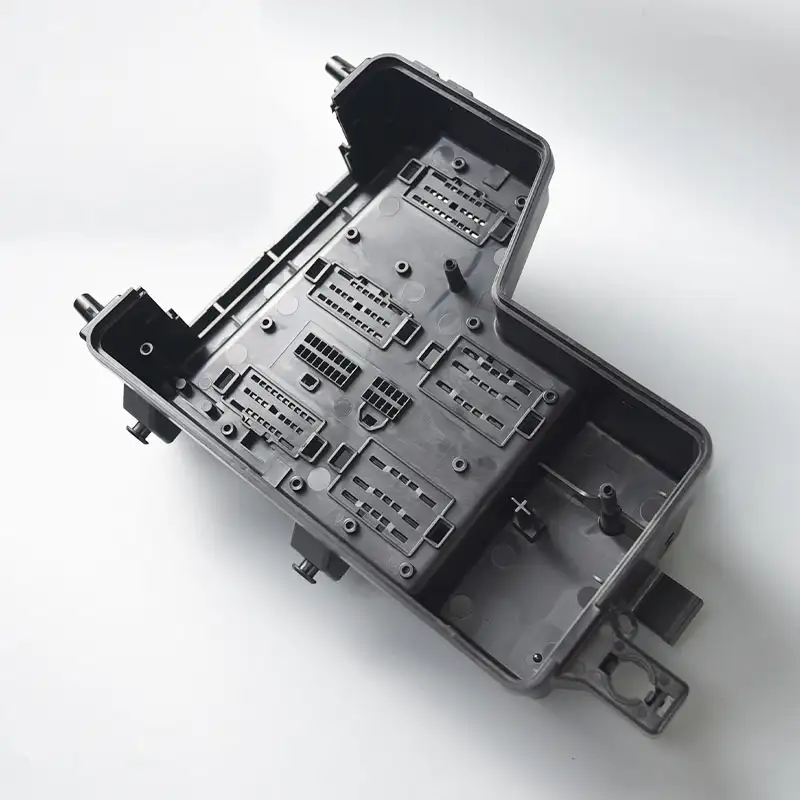

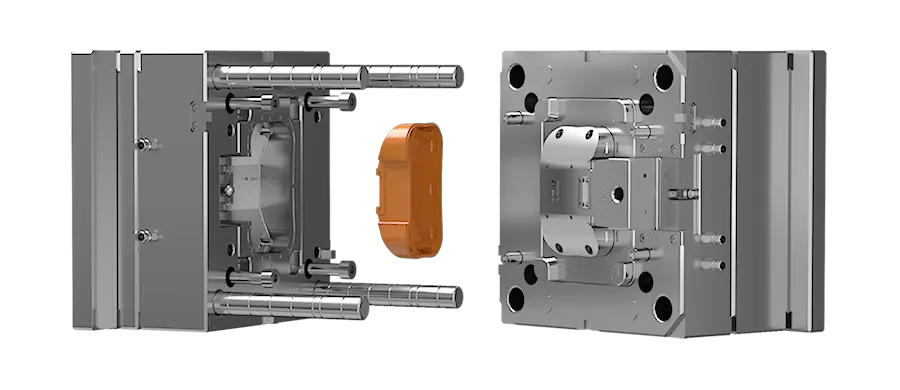

Bring product ideas to life from rapid prototyping to plastic injection molding production

Certifications

Get free manufacturability analysis to improve part design quickly. Get a free quotation for your project at a very competitive price.

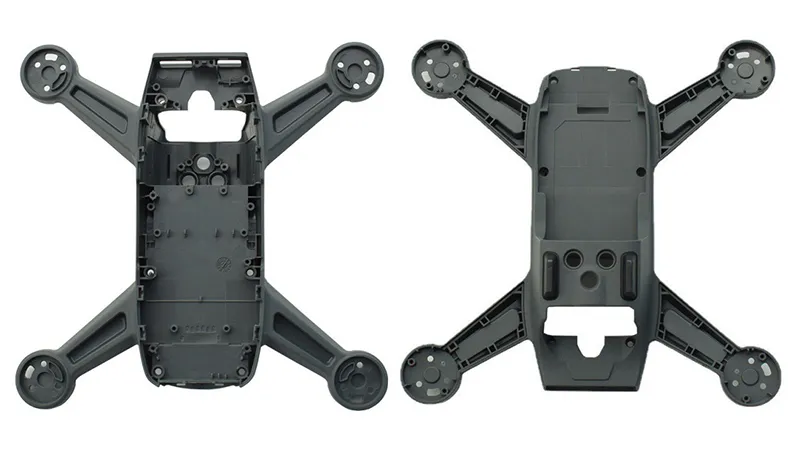

Quickly test prototype parts and push them to the market faster.

Tolerance up to ± 0.01 mm to meet your high precision plastic injection mold requirements to win in the market.

Precision plastic parts in production to reduce manufacturing costs and effectively meet your production needs.

| Standards | Details |

| Maximum Part Size | 1200×1000×300mm |

| Minimum Part Size | 1×1×1mm |

| Mold Cavity Tolerances | ±0.01mm |

| Mold Material | Steel and aluminum tools |

| Mold Type | Single, multi-cavity, and family molds; The production levels we provide: below 1000 times, below 5000 times, below 30000 times, above 100000 times. |

| Part to Part Repeatability | ±0.005mm |

| Tool Ownership | Customer owned |

| Secondary Operations | Mold texture, transfer printing, laser engraving, threaded inserts, and basic assembly. |

| Inspection and Certification Options | Quality reports such as FAI, ISO 9001, IATF16949 |

| Lead Time | 15 business days or less |

Worldbound China factory area is 27,000 square meters

Worldbound Vietnam factory covers an area of 36,000 square meters

More than 260 injection molding machines

More than 3,800 staff members

Copyright © 2023 :Worldbound Plasitc Products Co.Ltd