In the current era of continuous development of times and technology, the application of plastic injection molded parts products in the medical and healthcare industry is becoming increasingly popular. For customers, the processing price of medical injection molded parts is undoubtedly a focus of their concern. After all, this is related to people's livelihood issues. As a manufacturer of medical injection molded parts, the Worldbound Group should shoulder the obligation of a manufacturer of medical packaging and medical device accessories injection molded parts and try its best to reduce the processing price of medical injection molded parts to a lower level to reduce the cost of medical treatment for ordinary people.

Worldbound Plastics strictly selects materials in accordance with the conditions of health organizations and uses high-quality and moderately priced raw materials for manufacturing and production. In the production process, each process is strictly controlled, and full inspection of products is carried out. Employees are required to conduct self-inspection to ensure that defective products do not flow into the market.

If the post-production process is complicated and cumbersome, it will result in a large amount of waste of labor and material costs, thereby increasing the processing cost of medical injection molded parts. For this reason, when each new medical injection molded part project is launched, the engineering department of Worldbound will hold a discussion meeting and establish a project team. The purpose is to reduce the workload of the post-production process of the product without affecting the production and use functions, so as to achieve a win-win situation.

The Worldbound Group was established in 2002 and is located in Miaobian Industrial Zone, Liaobu, Dongguan, the capital of China's manufacturing industry, with convenient transportation and logistics. The company is a group enterprise that has been engaged in the design and manufacturing of precision molds and the production of precision injection molded products for many years.

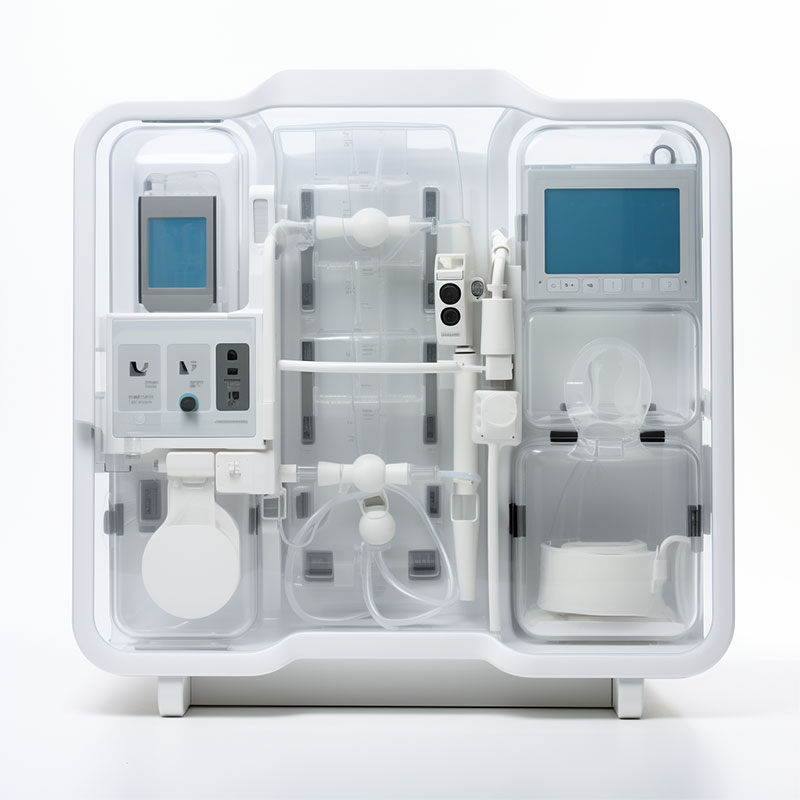

Focus on providing a complete set of solutions from product design, precision mold manufacturing, injection molding and assembly, and after-sales service for high-quality brands. Product application fields: Products are widely used in fields such as the outer casing and accessories of household appliances, injection molded parts for medical and healthcare devices, and injection molded parts for cosmetics packaging.

After years of precipitation and exquisite technology, it has successively obtained Dongguan high-tech enterprise, transformation and upgrading demonstration enterprise, and passed ISO9000, ISO14000 quality system certification, SA8000 social responsibility certification, SCAN anti-terrorism certification, Disney certification, 3C certification, NBCU certification, etc.

The company's customers are spread across more than 200 countries and cooperate closely with many well-known brands, such as Samsung, Xiaomi, Xiaoxiong, OPP, Huawei, Dior, L'Oreal, etc.

The company takes "stable quality and customer satisfaction" as its quality policy. By utilizing years of mold manufacturing experience, excellent production processes and advanced processing and manufacturing equipment, it wholeheartedly provides high-quality and fast services to customers and has won the trust and support of many enterprises from all over the world.

The company always adheres to the forefront of the manufacturing industry. While giving full play to the advantages of the original manufacturing industry such as seeking truth from facts, being diligent and hardworking, and lean production, it actively responds to the national call for "the transformation of traditional manufacturing industries to the Internet +", so that physical factories also have the wings of the Internet! Achieved good results with 91% of sales coming from online Internet customers.

Welcome new and old customers from all walks of life to visit and guide! As a group enterprise that has been engaged in the design and manufacturing of precision molds and the production of precision injection molded products for many years, Worldbound Plastics looks forward to cooperating with you. Welcome to inquire.

Copyright © 2023 :Worldbound Plasitc Products Co.Ltd