The quality of injection-molded precision medical devices is crucial to patients' health and treatment outcomes in the medical field. However, its production process faces numerous challenges. From the selection of raw materials to mold manufacturing, from the regulation of process parameters to environmental control, and then to quality inspection and feedback, every step requires meticulous control. The following will provide an in-depth analysis of how to effectively ensure the product quality.

1.1 Basis for Material Selection

The selection of materials for precision medical device injection molding should consider multiple factors to ensure that the materials are suitable for their functions and application environments.

Biocompatibility: The materials must have no adverse reactions when in contact with the human body. For example, implantable devices require materials with high biocompatibility to ensure long-term implantation safety.

Chemical Stability: The materials should be able to resist various chemical substances in the medical environment to prevent performance degradation caused by chemical reactions and thus affect the quality of the devices.

Physical Properties:

Strength: Select materials with appropriate strength according to the force-bearing conditions of the devices. For example, surgical instruments need to be resistant to breakage, and implantable devices should be able to withstand the stress of the human body.

Elastic Modulus: For materials of vascular stents, the elastic modulus should match that of human blood vessels to ensure proper support and compliance.

Therstalbility: Consider the temperature changes during injection molding and use. For example, the high-temperature disinfection process requires materials that do not deform.

1.2 Supplier Screening and Management

Evaluation of Key Supplier Indicators

Production Qualifications: Possess legal production licenses and quality certifications.

Quality Control System: Have a complete process to ensure product quality.

Industry Reputation: Select suppliers with good reputations by referring to peer evaluations, etc.

Establishment of Long-Term Cooperative Relationships

Stability: Ensure the stability of the supply quantity and delivery time of raw materials.

Quality Consistency: Let suppliers have a deep understanding of the requirements to ensure stable quality.

1.3 Inspection Process of Raw Materials

Raw materials need to be comprehensively and strictly inspected upon entering the factory.

Appearance Inspection: Observe the color, transparency, and presence of impurities, etc., to preliminarily judge the quality.

Physical Property Testing:

Density: Measure to determine the composition and the presence of doping.

Hardness: Understand the wear-resistant and compressive properties.

Chemical Property Analysis

Composition Analysis: Confirm that the chemical composition meets the standards.

Purity Testing: Ensure the purity of the materials to guarantee the performance and safety of the devices.

Testing of Characteristics Related to Injection Molding Process

Flowability: Affects injection molding. Select materials with appropriate flowability according to the products.

Shrinkage Rate: Improper control will lead to product size deviation. Select materials with an appropriate shrinkage rate.

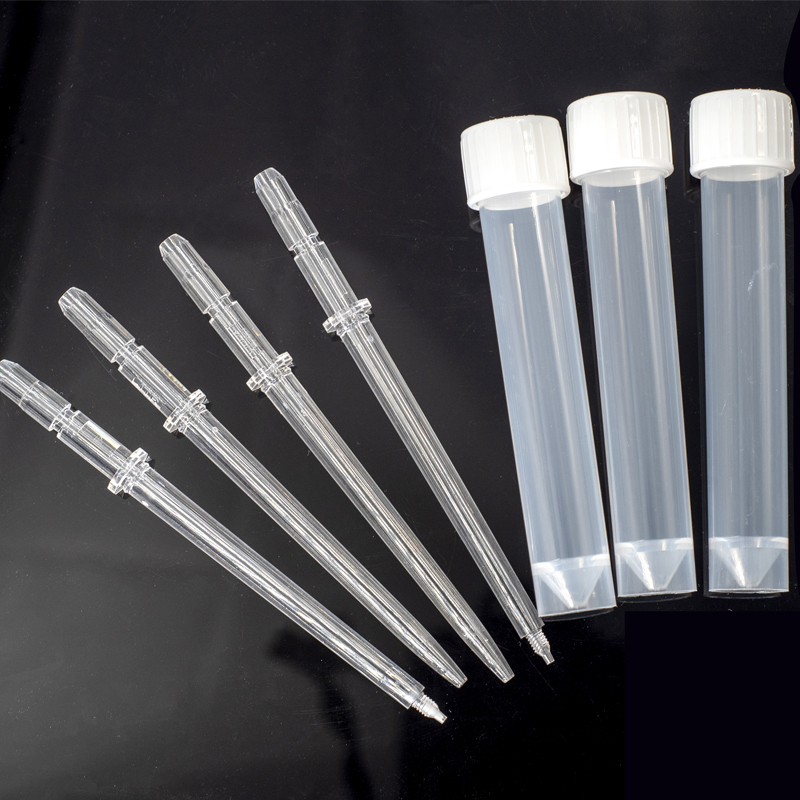

2.1 Requirements for High-Precision Molds

Precision medical device injection molding has strict requirements for mold precision, which is closely related to the quality of injection-molded products.

Cavity Dimension Precision: It needs to reach the micron or even nanometer level. Minor deviations will affect the product size and the performance of medical devices, such as molds for micro-components.

Surface Finish: The mold surface should be smooth to facilitate the uniform flow of the melt, avoid surface defects of the products, and improve the appearance quality, such as the shell of wearable devices.

Ejection Mechanism Design: Carefully design the ejection mechanism to ensure that complex and high-precision products can be smoothly ejected without damage, such as injection-molded parts with thin walls or fine structures.

2.2 Mold Manufacturing Processes and Technologies

Apply advanced processes and technologies to meet the high-precision requirements of molds.

Electrical Discharge Machining (EDM): Remove metal by pulsed discharge between the electrode and the workpiece, precisely control the machining dimensions, and shape complex cavities to meet the precision requirements of molds with special shapes.

CNC Machining: Utilize CNC programs to control the movement of machine tools to perform high-precision machining of mold components, ensure consistent precision in batch production, and guarantee product quality.

Precision Grinding: Perform fine grinding on key parts of the mold to improve the surface finish, make the melt flow smoothly, and reduce surface defects of the products.

2.3 Mold Verification and Maintenance

Molds need to be strictly verified and maintained before and during production to ensure product quality.

Verification before Mold Production

Trial Molding: Actually perform injection molding to test the performance of the mold and the quality of the products. If they do not meet the requirements, adjust and improve them.

Product Dimension Measurement: Compare the dimensions of the trial-molded products with the designed dimensions, analyze the reasons for the deviations, and take corresponding measures.

Appearance Inspection: Check the appearance defects of the trial-molded products and solve the problems targeted.

Maintenance during Mold Use

Cleaning: Regularly clean the mold to remove impurities, ensure the heat dissipation effect, and maintain the product quality.

Lubrication: Lubricate the moving parts to reduce wear, extend the service life, and ensure smooth ejection.

Replacement of Worn Parts: Timely replace the worn parts to maintain the precision and normal operation of the mold.

3.1 Key Process Parameters

In precision medical device injection molding, these key process parameters affect the product quality.

Injection Pressure: Excessive injection pressure will cause flash, overflow, etc., while insufficient pressure will result in insufficient filling, both of which affect the product quality.

Injection Speed: Too fast injection speed is prone to entrain air and form bubbles, while too slow speed will increase the melt viscosity and cause filling difficulties.

Holding Pressure Time: The length of the holding pressure time affects the density, size precision, and internal quality of the product. Too short a time will cause sink marks and internal voids, etc., while too long a time will increase the internal stress.

Cooling Time: Insufficient cooling time will cause the product to deform and have unstable size, while too long a time, although the product can be fully cured, will affect the production efficiency and performance.

Mold Temperature: An appropriate mold temperature helps the melt to flow uniformly. Too high or too low a temperature will affect the forming quality of the product.

3.2 Parameter Optimization and Setting

It is necessary to precisely optimize and set the process parameters to ensure product quality.

Design of Experiments (DOE): Systematically change multiple parameters and observe their effects on product quality to determine the optimal combination.

Simulation Analysis Software (such as Moldflow): Utilize software to simulate the injection molding process, predict problems, and adjust the parameters accordingly to optimize the quality.

Combination with Product Characteristics and Material Properties: Different product structures and material properties require corresponding adjustments of the process parameters.

3.3 Real-Time Monitoring of Process Parameters

Monitoring Equipment and Technology: Equip with temperature, pressure sensors and data acquisition systems, etc., to monitor the parameter status in real time.

Detection of Abnormalities and Adjustment Measures:Immediately take adjustment measures to ensure product quality when detecting abnormal fluctuations of the parameters.

4.1 Cleanliness Requirements

Different Grade Standards: Precision medical device injection molding needs to meet different cleanroom standards such as ISO 17442 according to the type of medical device and production stage. Implantable devices and the like have higher requirements.

Importance of Clean Environment: A clean environment can prevent impurities from mixing into the products, ensure the biocompatibility and safety of the products, and even minor pollution may cause serious consequences.

4.2 Temperature and Humidity Control

Effects on Materials and Molds: Temperature and humidity affect the performance of injection molding materials and the condition of molds. High temperature can cause material deformation and affect product quality; low humidity is prone to generate static electricity and attract impurities. Inappropriate temperature and humidity will cause mold deformation and rust.

Control Measures: Use air conditioners to adjust the temperature and dehumidifiers to reduce the humidity, and equip with temperature and humidity sensors to monitor and adjust in real time.

4.3 Static Electricity Protection

Static Electricity Hazards: Static electricity discharge can damage the electronic components of the product, adsorb impurities, and affect the function, appearance, and biocompatibility.

Protection Measures: Install static eliminators to neutralize static electricity, use anti-static materials to make tooling fixtures, and have workers wear anti-static clothing, etc., to eliminate the impact of static electricity.

5.1 Multi-Dimensional Quality Inspection

Appearance Inspection: Visually inspect the surface of injection-molded products for scratches, bubbles, flow marks, etc., which affect the appearance and user experience. Thorough inspections are required at all production stages.

Dimension Measurement: Compare the actual and designed dimensions of the products. Minor deviations will cause assembly difficulties or affect the performance. Use precise tools to strictly measure the key dimensions.

Performance Testing

Mechanical Performance Testing: Detect the strength, hardness, and toughness, etc., to ensure the safety and reliability of surgical instruments and other devices when bearing external forces.

Biocompatibility Testing: Evaluate the reaction of the product in the human environment to ensure that it is harmless to the human body.

Chemical Stability Testing: Detect the stability after contact with chemical substances to ensure the safety and effectiveness of medical devices.

5.2 Online Detection Technologies

Optical Detection: Utilize optical principles to monitor the surface and dimensions of the products in real time, quickly detect scratches, bubbles, dimension deviations, etc.

Ultrasonic Detection: Analyze the internal situation of the products by transmitting and receiving ultrasonic signals, detect cavities, inclusions, etc., suitable for complex products.

Advantages of Online Detection: Can detect quality problems in real time and feed back, reduce costs and waste, and facilitate the optimization of production processes to improve efficiency and quality.

5.3 Quality Feedback and Continuous Improvement

Quality Feedback Mechanism: Timely feed back the inspection results to relevant departments. For example, feed back appearance problems to the production department and dimension deviations to the process department, so that each department can solve the problems.

Continuous Improvement: Based on the feedback information, optimize raw materials, molds, process parameters, etc., such as reselecting materials, repairing molds, optimizing parameters, to steadily improve the product quality.

In conclusion, to control the product quality in precision medical device injection molding, meticulous attention should be paid to each step from raw materials, molds, process parameters, production environment to quality inspection and feedback. Only by comprehensive strict requirements and continuous optimization and improvement can we ensure excellent product quality, meet the high standards of the medical industry, safeguard patients' health, and promote the stable development of the industry.

Copyright © 2023 :Worldbound Plasitc Products Co.Ltd