20-year high-end brand precision injection molded parts customization service provider.

21-Dongguan Worldbound Plastic Products Co., Ltd. is affiliated to Shibang Group. With a plant area of 27,000 square meters, its main products include molds, toys, electrical accessories, medical device accessories, home appliance accessories, electronic products, small household appliances, and pet supplies. It provides high-end brands with a complete set of integrated solutions covering product design, precision mold manufacturing, injection molding and assembly, and after-sales service.

Worldbound Group was founded in 2002. Centering on intelligent manufacturing and precision manufacturing, it employs a model of cooperation, co-construction, and win-win to integrate the upstream and downstream supply chains of manufacturing and optimize the entire industrial chain. It has become an intelligent manufacturing enterprise group integrating design and innovation, service and production. Under Shibang Group, there are eight manufacturing factories located in Dongguan, Guangzhou, Shenzhen, and Vietnam. There are also two research and development centers in Shanghai and Hong Kong. It has precision mold manufacturing workshops, dust-free injection molding production workshops, and dust-free surface treatment workshops. It is equipped with hundreds of advanced manufacturing equipment such as CNC machines, mirror spark workshops, various large and medium-sized injection molding production lines, die-casting and precision blow molding production lines, environmentally friendly vacuum aluminum sputtering coating production lines, fully automatic fuel injection production lines, bonding, SMT patch, and intelligent COB chip bondingproductionines.

With a 50-person engineering mold design team with over 20 years of experience, we accept custom designs from customer drawings or samples. Large quantities get free mold design and complimentary 3D samples.

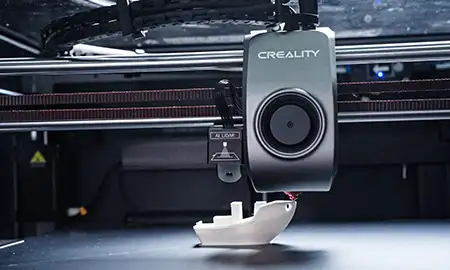

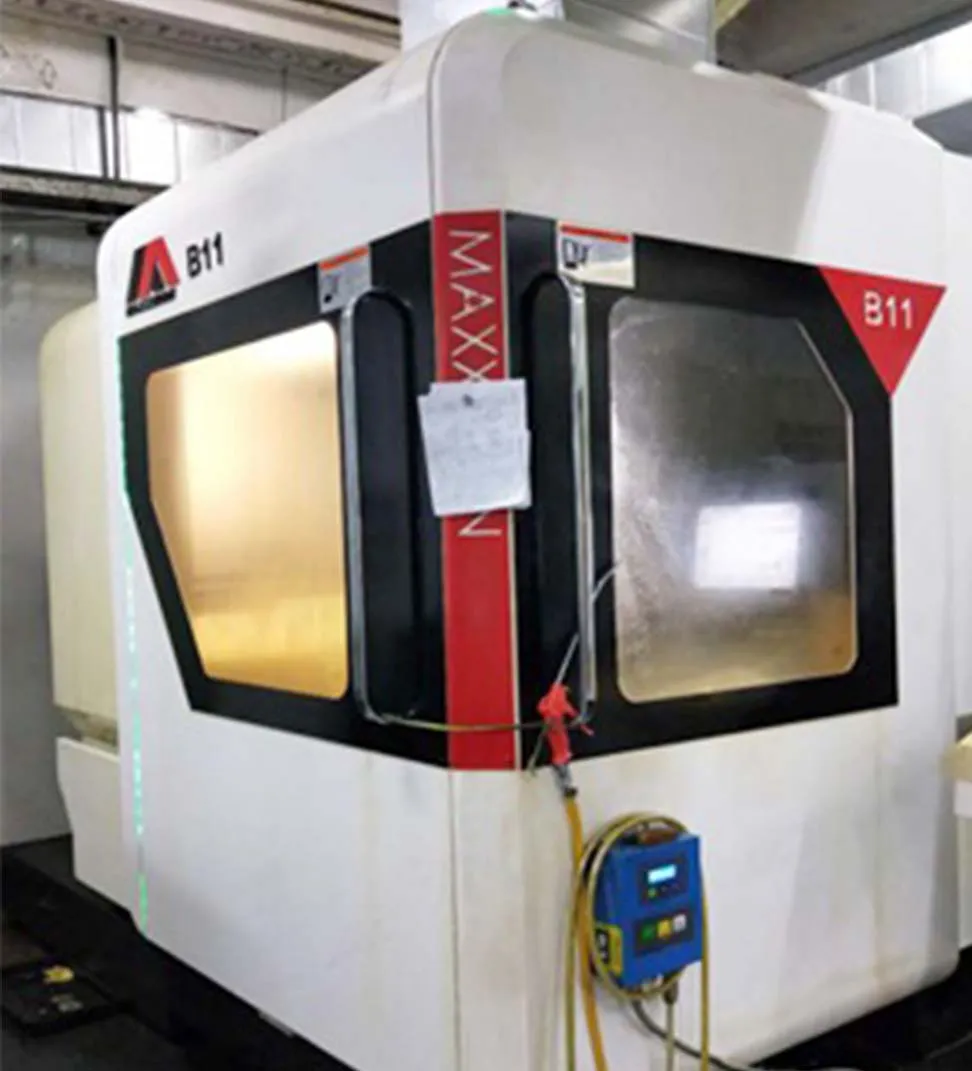

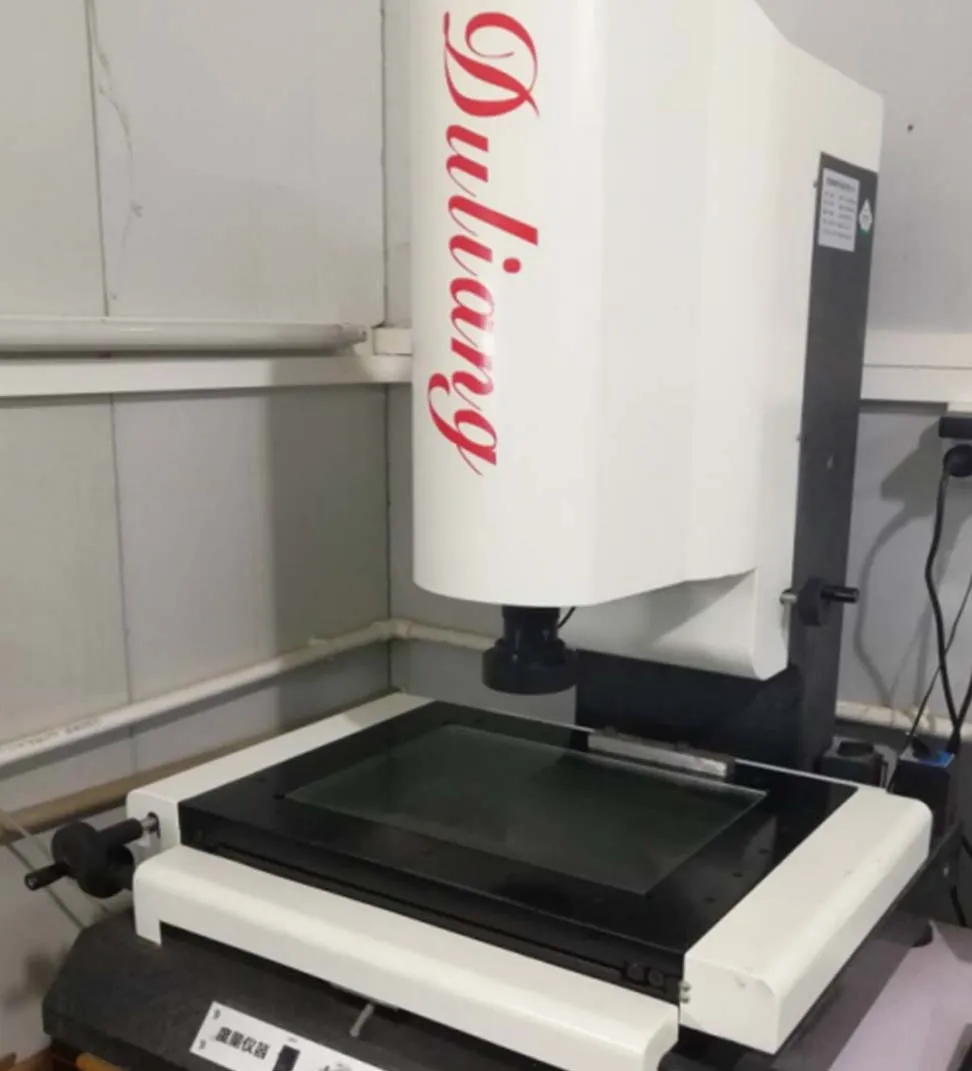

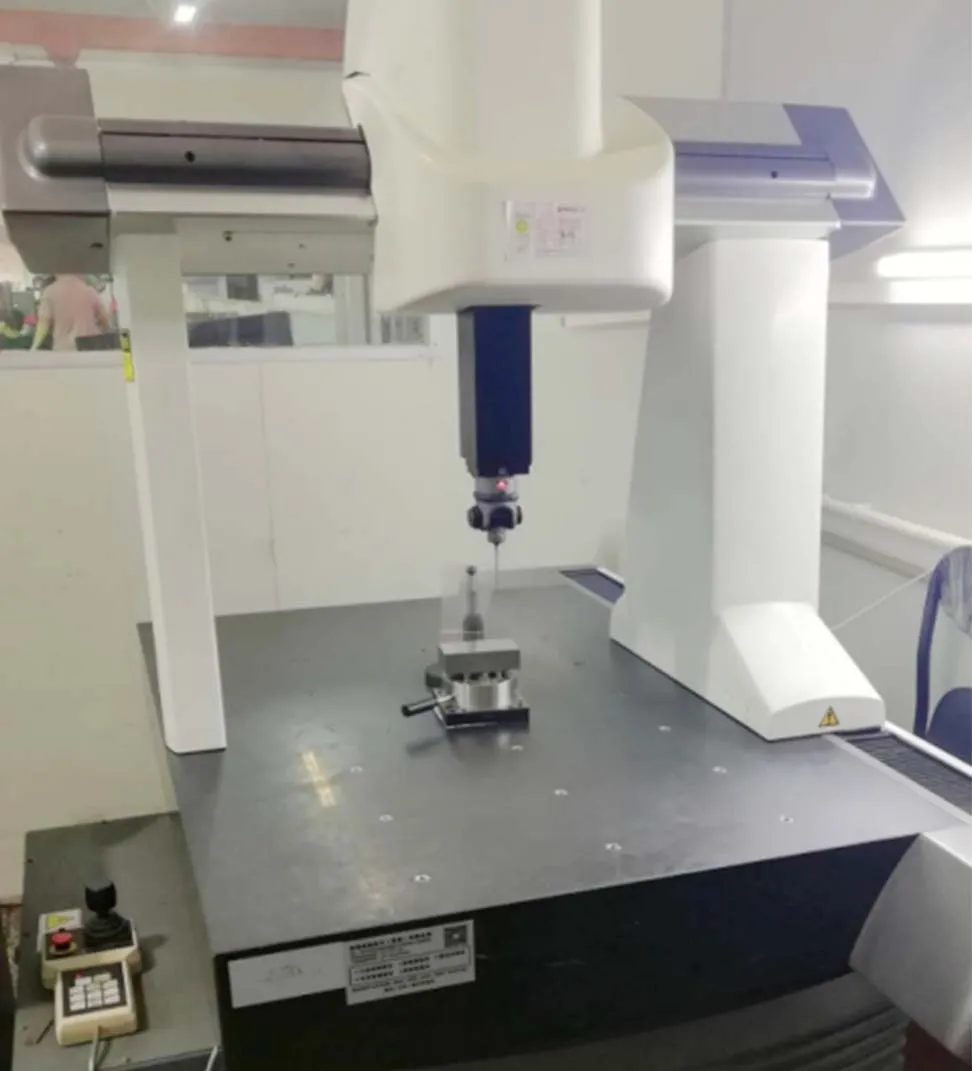

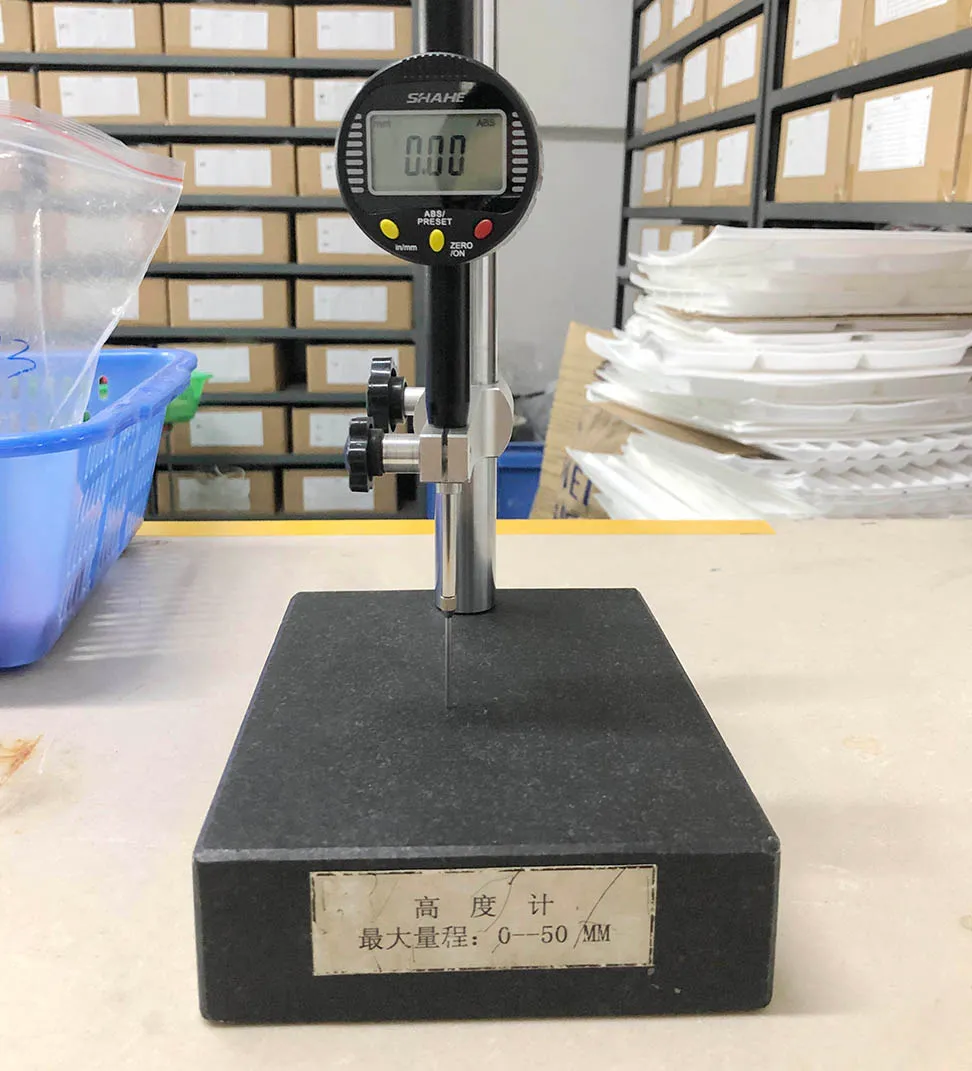

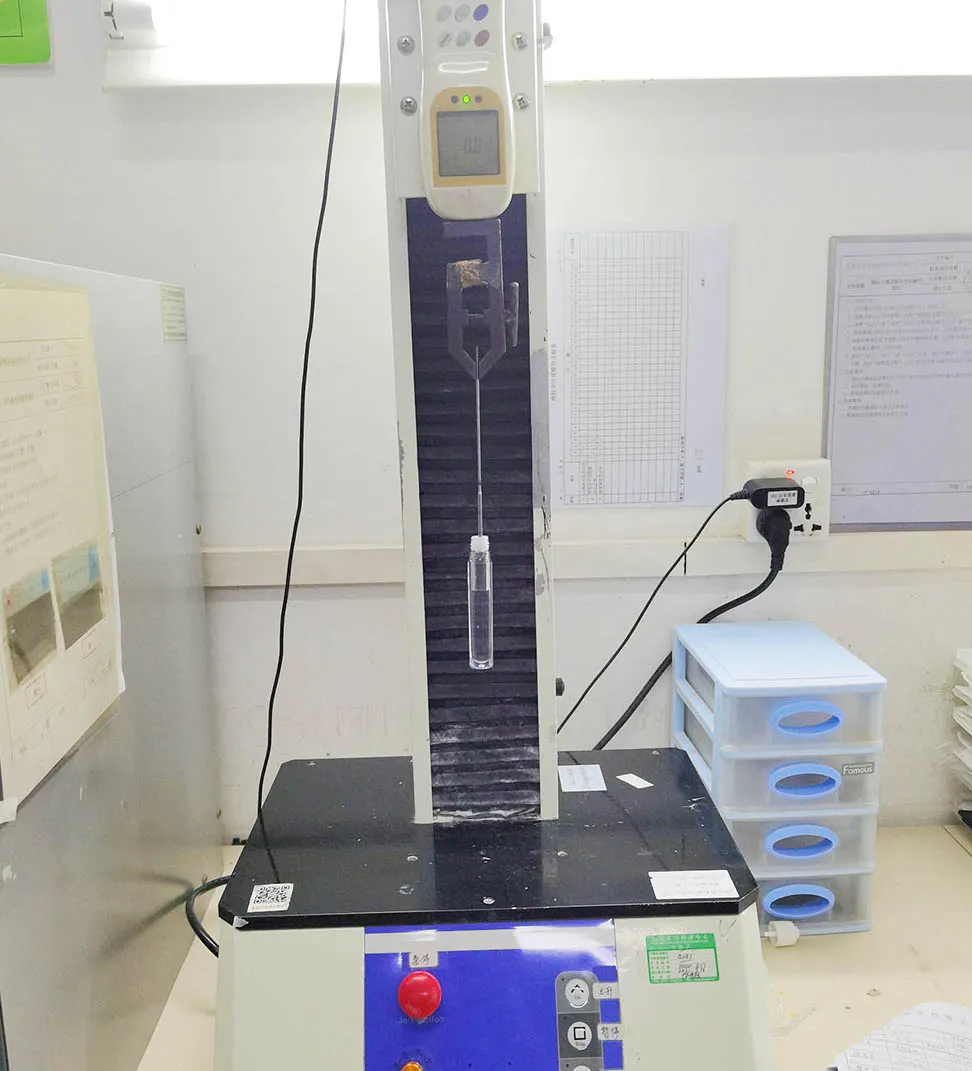

We can meet different product development design requirements based on structure and performance. Using high-speed precision cutting (30000RPM), precise mirror EDM, high-precision wire cutting, and 3D inspection equipment to ensure accuracy, smoothness, and no distortion.

With a complete production management team and advanced equipment, we handle injection molding, screen printing, painting, electroplating, hot stamping, assembly, and shipping. We've helped hundreds of clients achieve mass production.

Provide a complete set of solutions from product design/mold manufacturing/injection molding mass production.

Engineering team

CNC equipment

Milling equipment

Precision grinding machine

Makino mirror spark machine

Topedm Electrical Discharge Machining

Medium/Fast WEDM machine

Large deep hole drilling machine

Lathes

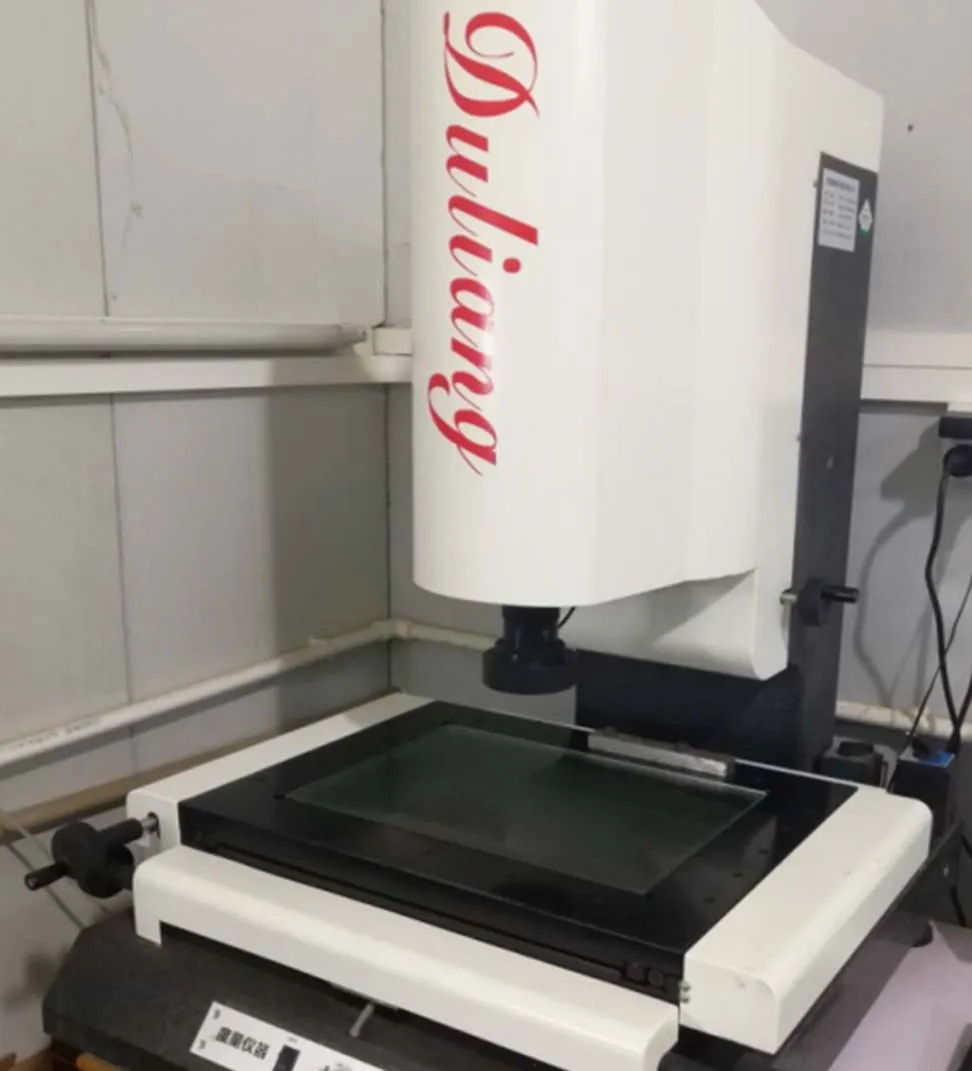

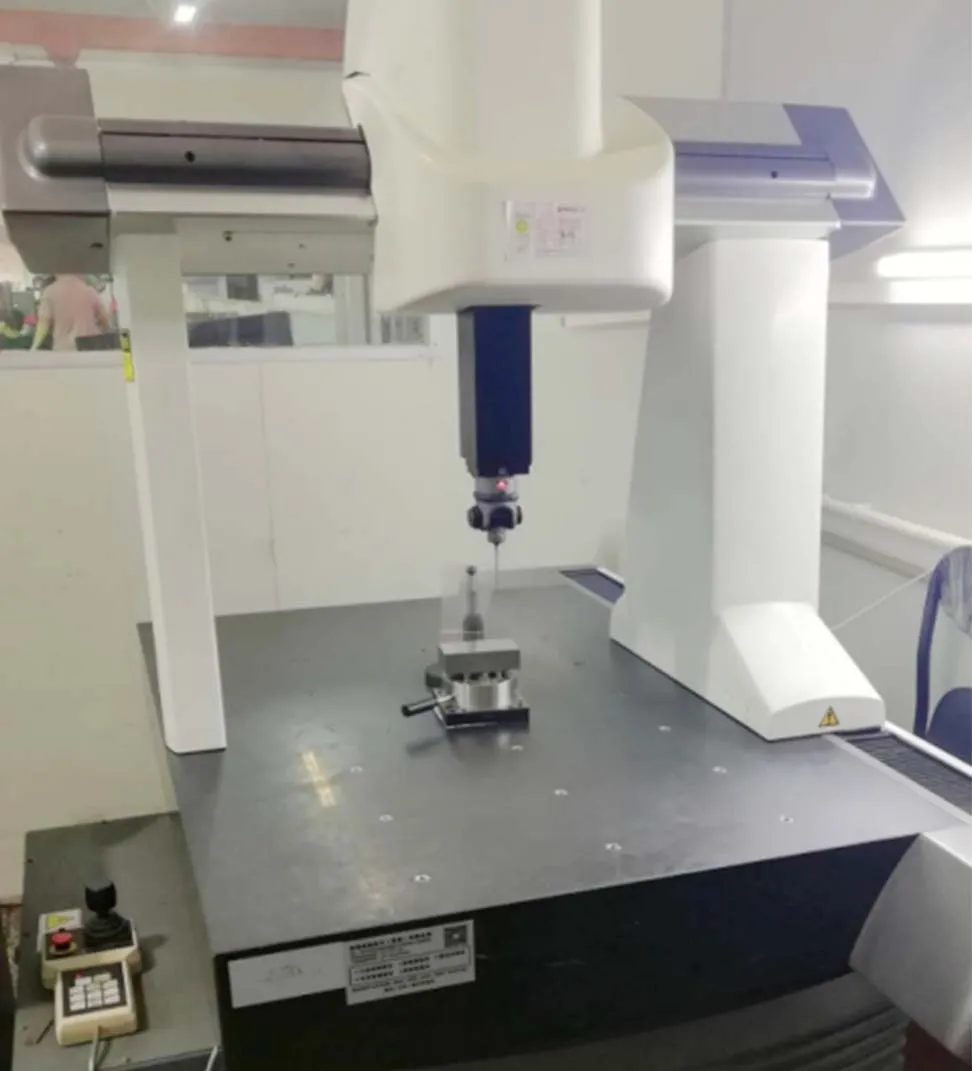

2D/3D Vision Measuring Machine

Engineering team

Mold manufacturing team

Milling machine

Injection molding department

Silk screen/pad printing/hot stamping

Spraying workshop/department

Assembly Department

Quality Assurance Control Team

PCB production department

other people

Copyright © 2023 :Worldbound Plasitc Products Co.Ltd